What Is The Extrusion Principle Of An Aluminium Extrusion Press Machine?

The working principle of the aluminium extrusion press machine, as its name suggests, involves extruding aluminum to shape it into the desired product. But do you fully understand the precise extrusion principle behind this process? For those interested in aluminium extrusion fabrication, gaining a clear understanding of the core functions of the aluminium extrusion press machine is essential. Jiuying’s detailed introduction below aims to provide valuable insights into this advanced fabrication method.

Hydraulic Extrusion Press Principle

Extrusion is a pressure processing method that applies force to one end of the billet inside the extrusion cylinder, pushing it through the die hole to form the desired shape. For producing pipes and profiles with complex cross-sections, extrusion is often the only feasible pressure processing method. Aluminum profile processing relies heavily on extrusion, which can be classified into two types: forward extrusion and reverse extrusion.

Forward Extrusion:

In forward extrusion, the metal flows in the same direction as the extrusion rod. Its main characteristic is the presence of significant external friction between the ingot and the inner wall of the extrusion cylinder.Reverse Extrusion:

In reverse extrusion, the metal flows in the opposite direction to the extrusion movement. Unlike forward extrusion, there is no relative sliding between the metal and the inner wall of the cylinder, eliminating external friction.

These differing characteristics between forward and reverse extrusion significantly affect the extrusion process, product quality, and production efficiency.

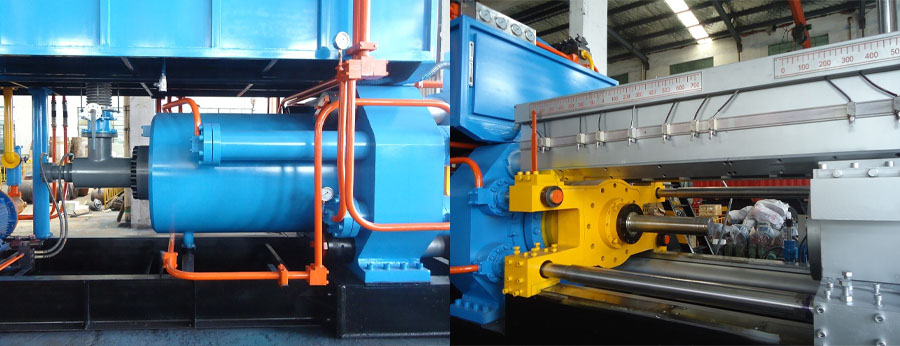

Structural Principle of the Hydraulic Extrusion Press

A complete hydraulic extrusion press system typically consists of three main parts: the mechanical part, hydraulic part, and electrical part.

Mechanical Part:

Includes components such as the machine base, guide pillars (tie rods), front and rear beam plates, insulation seat, mold seat, upper and lower guide rail plates, mechanical delivery system, extrusion rod base, and extrusion rod.Hydraulic System:

Comprises the main cylinder, auxiliary cylinder, locking cylinder, mold base cylinder, plunger pumps (variable and fixed), vane pumps (single and multi-pump combinations), valve plates, various hydraulic valves (e.g., one-way, overflow, reversing), oil pipes, oil tanks, and hydraulic switches.Electrical System:

Includes the power cabinet, operating table, PLC programmable controller, AC contactor, display screen, and other electrical components.

The Role of Main Components in Aluminium Extrusion Fabrication

1. The machine base is the carrier of all functions including the machine base, and is a closed part that bears the extrusion force.

2. The main cylinder is a hydraulic working cylinder that generates extrusion force and is of plunger-type structure.

3. Guide pillars, also known as tie rods, the front plate, and the main oil cylinder are fastened together by four guide pillars with nuts to form a closed stress-bearing system to withstand the pressure of the hydraulic press when it is working. The middle plate part and the butterfly plate of the main cylinder move forward and backward guided by four guide pillars. Therefore, in addition to the force, the guide column also acts as a guide rail for the moving beam and the extrusion cylinder.

4. The butterfly plate is a part used to balance the weight of the protruding part of the main plunger and control the center of the extrusion shaft.

5. The insulation seat, also known as the ingot tube, is used to install the aluminum ingot billet and is a high-pressure constant temperature container.

Other content recommendations

If your factory needs to manufacture aluminum profiles, we’re here to help! With our aluminium extrusion press machines, we provide tailored solutions to enhance production efficiency and reduce costs. Contact us today to discuss your needs or request a quote.

Contact: Mr. Liu (Manager)

WhatsApp/Mobile/WeChat: 008613394110095

Email: [email protected]

Website: www.aluextrusionpress.com

Let us help you optimize your manufacturing process and achieve better results!