Application of Frequency Converter in Hydraulic Servo Aluminum Profile Extrusion Machine

In the global energy shortage, the call for energy saving is getting louder and louder, and advanced energy-saving technology has gradually become a bright spot in society. Compared with the application of traditional motors in aluminum profile extrusion machines, permanent magnet synchronous motors are more energy-efficient, and this type of motor will become more and more popular in the application of aluminum profile extrusion machines.

A Brief Introduction of Aluminum Extrusion Press

As we introduced in the last several blogs, you probably have already known that what is an aluminum extrusion press. But there may will be some new friends, so I still want to give you a brief introduction of aluminum extrusion press.

The aluminum profile extrusion machine is an important method of pressure processing using the principle of high-temperature melting plastic forming of aluminum materials. Through extrusion, aluminum rods are processed into tubes, T-shaped, L-shaped, and other profiles at one time.

Then we all learn about this machine, but do you know about the power of aluminum extrusion press?

The working process of the aluminum profile extrusion machine is generally divided into feeding, jacking, extrusion, retreat, cutting, feeding, and periodic cycle. According to the process parameters such as extrusion coefficient and extrusion speed, the pressure of the hydraulic power system is required at each stage. and dynamic changes in flow.

The power of the aluminum profile extrusion machine comes from the hydraulic power system. The hydraulic part of the quantitative pump system of hydraulic equipment adopts an asynchronous motor oil pump system. The motor drives the oil pump to suck oil from the oil tank and pressurize it to output. The pressure, flow and direction of the oil are controlled by various control valves to ensure that the working mechanism operates with a certain force ( Or torque) and a certain speed to move in the required direction.

Problems Existing in Traditional Control of Aluminum Profile Extrusion Machine

A fixed-speed asynchronous motor is used to drive the quantitative pump, and the oil pump will output a constant flow rate. However, the process parameters such as extrusion coefficient and extrusion speed require dynamic changes in pressure and flow at each stage, and all excess high-pressure oil is returned to the oil tank through the relief valve. , there is a huge waste of energy.

Similarly, the greater the set pressure and flow rate, the greater the waste flowing back to the tank. When the wasted energy is turned into heat energy, increasing the oil temperature also causes many problems, such as the instability of the extrusion molding process, and the oil seal needs to be replaced frequently.

The aluminum profile industry is developing rapidly and the market competition is becoming increasingly fierce. It is an urgent need to reduce the unit consumption of products and save production costs to improve the competitiveness of products in the market.

Energy-saving principle of aluminum profile extrusion machine

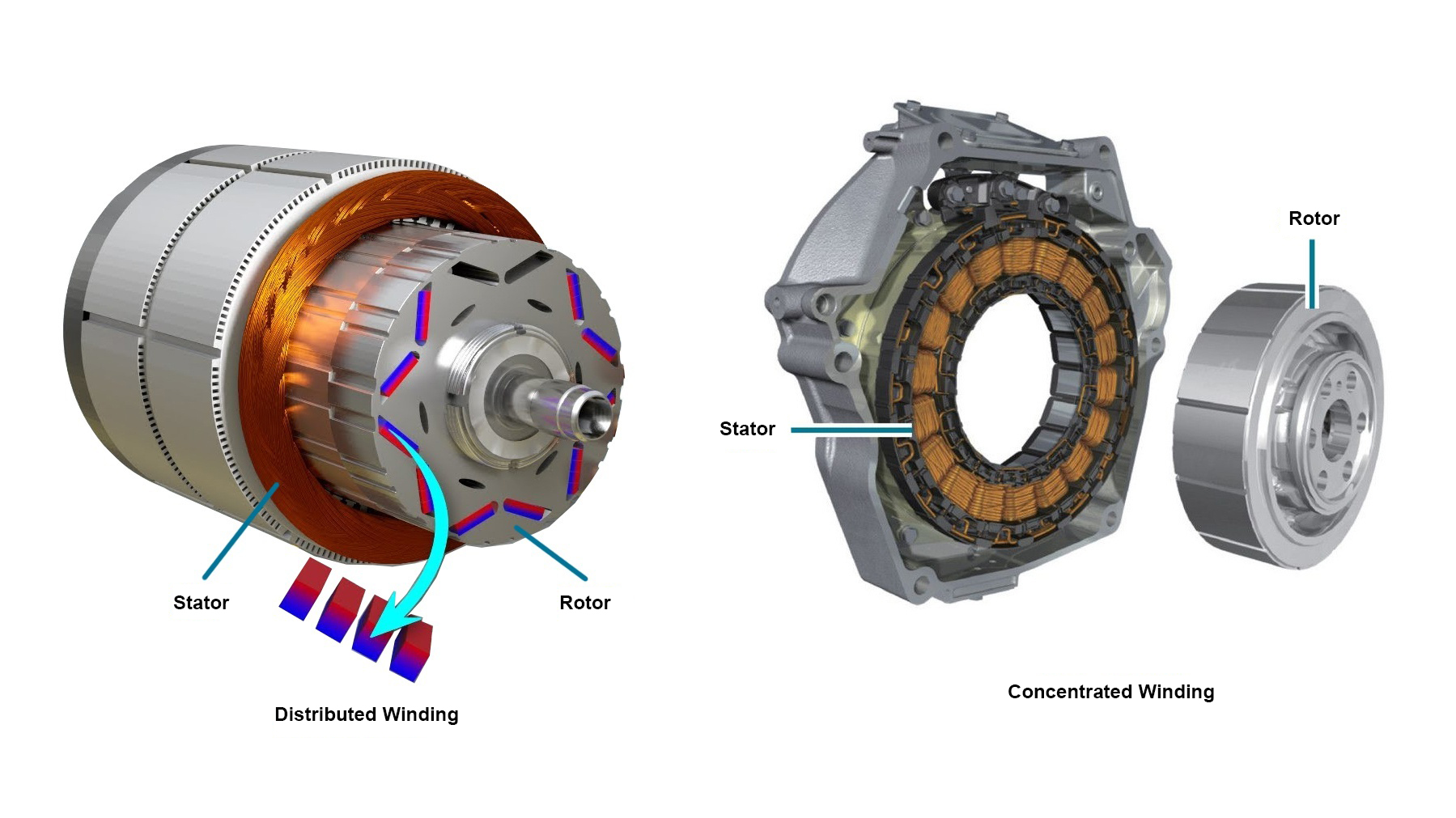

The permanent magnet synchronous motor is used to replace the original asynchronous motor, the original vane pump is replaced by the gear pump (screw pump, plunger pump), and the permanent magnet synchronous drive is added to form the control system of the aluminum profile extrusion machine, which is permanent magnet synchronous The control system replaces the traditional valve control, adopts double closed-loop control for the pressure and flow required for production, and can work reliably even under low pressure.

At the same time, because the permanent magnet synchronous motor has the characteristics of the fast start and stop, it can start or stop within 30 milliseconds, thereby realizing continuous control of the flow and pressure output of the oil pump, and greatly improving the repeatability of the hydraulic press. The output flow rate of the gear oil pump driven by the permanent magnet synchronous motor is basically consistent with the actual demand pressure speed of the system. The permanent magnet synchronous motor outputs as much as the actual demand pressure speed, so as to reduce the output waste of the gear oil pump and achieve energy savings. In the stages of pressure holding and cooling, the permanent magnet synchronous motor has almost no power consumption.

The characteristics of the modification of permanent magnet synchronous motor for aluminum profile extrusion machine

(1) Control Precision

The control accuracy of the permanent magnet synchronous motor is determined by the rotary encoder at the rear end of the motor shaft. Taking the 1024 sensor pulse number of the rotary encoder as an example, it can generally reach 1/1024 per week.

(2), low-frequency characteristics

The AC permanent magnet synchronous motor runs very smoothly, and there will be no vibration even at low speeds. The permanent magnet synchronous motor system has a resonance suppression function, which can cover the lack of mechanical rigidity, and the system has a frequency analysis function (FFT) inside the system, which can detect the mechanical resonance point and facilitate system adjustment.

(3), moment-frequency characteristics

The permanent magnet synchronous motor has a constant torque output, that is, it can output a rated torque within its rated speed (generally 2000RPM), and it is a constant power output above the rated speed. The speed climbs and the torque decreases.

(4), overload capacity

A permanent magnet synchronous motor has a strong overload capacity. Its maximum torque is twice the rated torque, which can be used to overcome the moment of inertia of the inertial load at the moment of starting.

(5), running performance

The permanent magnet synchronous motor drive system adopts closed-loop control. The drive can directly collect the feedback signal of the motor encoder, and the internal position loop and speed loop are formed. Generally, there will be no stop loss or overshoot of the stepping motor, and the control performance is better. reliable.

(6) Response performance

The acceleration performance of the permanent magnet synchronous motor system is good. It only takes tens of milliseconds to accelerate from a standstill to its rated speed of 2000 RPM. It can be used in control occasions that require fast start and stop.

The Future Trend of Permanent Magnet Motor Application in Aluminum Extrusion Press

The application is based on the permanent magnet synchronous motor's wide speed range, strong overload capacity, good running stability, high-speed control accuracy, fast response speed, suitable for frequent start and stop, and smaller volume and lighter weight than asynchronous motors. It is very suitable to be applied to the power drive and system control of aluminum extrusion presses. And because it’s energy-saving ability, its application in aluminum extrusion press is going to be more and more popular in the future.