Revolutionizing Metalwork with Stainless Steel Induction Furnaces

In the ever-evolving world of metalworking, the quest for efficiency, precision, and environmental responsibility drives innovation. Among the myriad advancements, the stainless steel induction melting furnace stands out as a groundbreaking technology. These furnaces are revolutionizing the way metals are melted and refined, offering unparalleled advantages that cater to the needs of modern industries. In this comprehensive blog, we delve into the intricacies of stainless steel induction melting furnaces, exploring their working principles, advantages, applications, and why they are becoming the preferred choice for metalworkers worldwide.

Understanding Induction Melting Technology

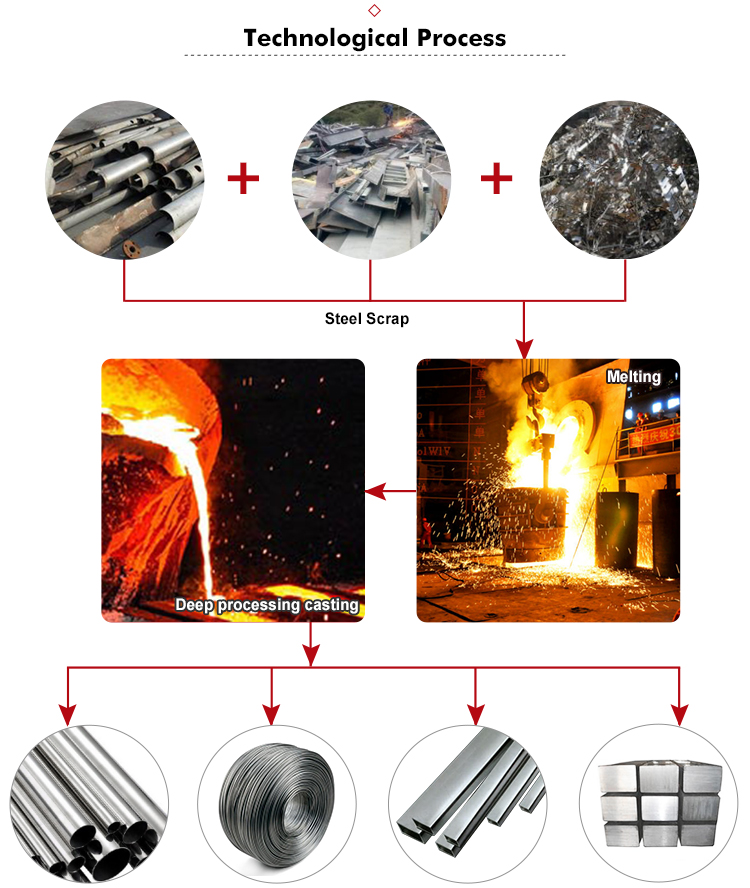

Induction melting is a process that utilizes electromagnetic induction to generate heat within a conductive material. This technology is distinguished by its ability to precisely control the heating process, making it ideal for melting metals like stainless steel. The core components of an induction melting furnace include an induction coil, a power supply, and a crucible.

Working Principle:

When an alternating current passes through the induction coil, it creates a rapidly changing magnetic field. This magnetic field induces eddy currents within the metal placed inside the crucible. The resistance of the metal to these eddy currents generates heat, melting the metal uniformly and efficiently.

Advantages of Stainless Steel Induction Melting Furnaces

Induction melting furnaces are known for their energy efficiency. They require less energy to achieve the desired melting temperature compared to traditional methods, resulting in cost savings and reduced carbon footprint.

The ability to precisely control the heating process allows for uniform melting, minimizing the risk of hot spots or incomplete melting. This precision ensures high-quality metal output with consistent properties.

Induction furnaces can rapidly achieve high temperatures, significantly reducing melting times. This increased efficiency translates to higher productivity and faster turnaround times for metalworking operations.

Induction melting is a contactless process, reducing the risk of contamination and exposure to harmful fumes. Additionally, the absence of open flames or combustible materials enhances workplace safety.

Stainless steel induction melting furnaces can handle a wide range of metal alloys, making them versatile for various applications. They are suitable for melting ferrous and non-ferrous metals, including stainless steel, aluminum, copper, and more.

Applications of Stainless Steel Induction Melting Furnaces

The versatility and efficiency of stainless steel induction melting furnaces make them indispensable across numerous industries. Some notable applications include:

Induction furnaces are widely used in foundries for melting and casting metals. Their precise control ensures high-quality castings with minimal defects.

The automotive sector relies on induction melting for producing components like engine blocks, transmission parts, and other critical metal parts.

Induction melting furnaces play a crucial role in the aerospace industry, where the demand for lightweight, high-strength metal alloys is paramount.

The jewelry industry benefits from the precise melting capabilities of induction furnaces, enabling the creation of intricate designs and high-purity metals.

Induction melting is also employed in metal recycling processes, facilitating the efficient recovery and reuse of valuable metals.

Why Choose Our Stainless Steel Induction Melting Furnaces?

At Jiuying, we are committed to providing state-of-the-art stainless steel induction melting furnaces that meet the highest standards of quality and performance. Here’s why you should choose our products:

Our induction melting furnaces incorporate the latest technological advancements, ensuring superior performance, energy efficiency, and reliability.

We understand that each industry and application has unique requirements. Our team works closely with clients to design and deliver customized solutions tailored to their specific needs.

We adhere to rigorous quality control processes to ensure that our furnaces meet and exceed industry standards. Our commitment to quality guarantees long-lasting and dependable equipment.

Our experienced team of engineers and technicians provides comprehensive support, from installation and commissioning to ongoing maintenance and troubleshooting.

We prioritize sustainability in our manufacturing processes, developing energy-efficient and environmentally friendly induction melting furnaces.

Welcoming Orders

We invite you to explore the transformative capabilities of our stainless steel induction melting furnaces. Whether you are in the automotive, aerospace, jewelry, or recycling industry, our innovative solutions will elevate your metalworking processes to new heights. Contact us today to discuss your requirements, and let us help you achieve unparalleled efficiency, precision, and productivity in your operations.

Industry Furture

Stainless steel induction melting furnaces are revolutionizing the metalworking industry with their unmatched efficiency, precision, and versatility. By harnessing the power of electromagnetic induction, these furnaces deliver superior melting performance while reducing energy consumption and environmental impact. At Jiuying, we are dedicated to providing cutting-edge induction melting solutions that empower industries to achieve their goals. Embrace the future of metalworking with our state-of-the-art stainless steel induction melting furnaces and experience the difference in quality and performance.