Electric Resistance Furnaces: Technology, Applications, Benefits

Electric resistance furnaces have emerged as essential tools in various industrial processes, providing a reliable and efficient means of heat treatment. This blog explores the technology behind electric resistance furnaces, their diverse applications, and the numerous benefits they offer to industries worldwide. If you're considering upgrading your heat treatment processes, we welcome you to explore our comprehensive range of electric resistance furnaces designed to meet your specific needs.

What is an Electric Resistance Furnace?

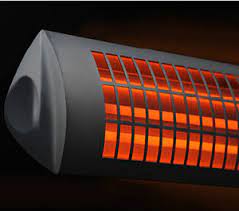

An electric resistance furnace is a type of furnace that utilizes electrical resistance to generate heat. The core principle revolves around converting electrical energy into heat energy through resistive heating elements, typically made of nickel-chromium alloys or silicon carbide. These elements are strategically placed inside the furnace chamber, where they emit heat as electricity passes through them, raising the temperature to the desired level.

Our electric resistance furnaces are available in various configurations, including box furnaces, tube furnaces, and muffle furnaces, each designed to cater to specific industrial needs. These furnaces are known for their precision in temperature control, making them ideal for processes that require consistent and accurate heat treatment. If you're looking for reliable heat treatment solutions, we invite you to contact us to learn more about our customized furnace options.

How Electric Resistance Furnaces Work

The operation of an electric resistance furnace is straightforward yet highly effective. Key components include heating elements, insulation, temperature control systems, and a power supply.

The heating elements are the core of the furnace, responsible for generating heat through electrical resistance. The furnace chamber is lined with high-quality insulation materials to minimize heat loss and ensure energy efficiency, maintaining a stable temperature. Modern electric resistance furnaces are equipped with advanced temperature control systems, including thermocouples and digital controllers, which monitor and regulate the temperature with high precision.

When the furnace is turned on, electricity flows through the heating elements, causing them to resist the electrical current. This resistance generates heat, which is radiated into the furnace chamber, raising the temperature. The insulated chamber ensures that the heat is retained, creating a controlled environment for the heat treatment process.

If you're interested in learning more about how our electric resistance furnaces can enhance your production processes, we're here to assist you. Feel free to reach out to us with any inquiries or to request a customized quote.

Applications of Electric Resistance Furnaces

Electric resistance furnaces are widely used across various industries due to their versatility and efficiency. One key application is the heat treatment of metals. Our electric resistance furnaces are commonly used for annealing, tempering, and hardening metals. The precise temperature control allows for uniform heat distribution, ensuring consistent results in metal processing.

In the ceramics industry, these furnaces are used to fire clay and other materials at high temperatures, resulting in durable and finished ceramic products. Our furnaces are also essential in laboratory settings for conducting material testing, chemical analysis, and sample preparation. Their ability to maintain specific temperatures makes them ideal for scientific experiments.

The glass industry relies on electric resistance furnaces for processes like glass annealing and tempering. These furnaces help control the cooling rate of glass, preventing defects and ensuring product quality. In powder metallurgy, electric resistance furnaces are used for sintering metal powders into solid objects. The controlled heating process facilitates the bonding of powder particles, resulting in high-strength components.

Whatever your industry, we offer a range of electric resistance furnaces tailored to your specific applications. We welcome the opportunity to discuss how our products can support your operational goals.

Advantages of Electric Resistance Furnaces

The popularity of electric resistance furnaces stems from the numerous advantages they offer over other types of furnaces. One significant advantage is precision temperature control. Our electric resistance furnaces provide unparalleled accuracy in temperature regulation, making them suitable for processes that demand exact heat treatment conditions.

Energy efficiency is another critical benefit. The high level of insulation in our furnaces reduces heat loss, leading to significant energy savings. Additionally, the ability to precisely control the temperature minimizes energy consumption, resulting in lower operational costs. Our furnaces are also environmentally friendly, producing no harmful emissions, making them an ideal choice for industries looking to reduce their carbon footprint.

In terms of maintenance, our electric resistance furnaces have fewer moving parts compared to other furnace types, resulting in lower maintenance requirements. The heating elements are durable and long-lasting, further reducing the need for frequent replacements. These furnaces are versatile, capable of being used for a wide range of applications, from metal processing to ceramics and laboratory testing. Their adaptability makes them a valuable asset in various industries.

Safety is another key advantage. Our electric resistance furnaces are generally safer to operate than fuel-based furnaces, as they do not involve open flames or combustible materials. This reduces the risk of accidents and enhances workplace safety.

We are committed to providing furnaces that deliver these benefits to your operations. If you’re considering upgrading or expanding your heat treatment capabilities, we invite you to explore our selection of electric resistance furnaces and welcome your inquiries.

Choosing the Right Electric Resistance Furnace

When selecting an electric resistance furnace for your industrial needs, several factors should be considered. First, determine the maximum and minimum temperature requirements for your process. Ensure that the furnace can achieve and maintain these temperatures consistently.

The size of the furnace chamber is also crucial. It should accommodate the size and quantity of the materials being processed. Consider the available space in your facility when choosing the furnace size. Our team can assist you in selecting the right size and configuration to meet your operational needs.

Energy efficiency is another critical factor. Look for furnaces with high insulation quality and energy-efficient heating elements. This will help reduce operational costs and minimize energy consumption. Additionally, opt for furnaces with advanced temperature control systems that offer precise regulation and monitoring. Digital controllers and programmable settings can enhance the efficiency of your process.

Evaluate the maintenance needs of the furnace, including the durability of the heating elements and the ease of replacing parts. Choose a furnace that requires minimal maintenance to ensure uninterrupted operation. Lastly, select a reputable manufacturer that offers reliable customer support and after-sales service. This will ensure that you have access to technical assistance and spare parts when needed.

We are here to guide you through the process of selecting the ideal electric resistance furnace for your needs. Contact us today to discuss your requirements and learn how we can provide the best solutions for your business.

The Future of Electric Resistance Furnaces

As industries continue to prioritize energy efficiency and environmental sustainability, electric resistance furnaces are expected to play an increasingly significant role in various sectors. Advances in material science and furnace technology will likely lead to the development of even more efficient and versatile electric resistance furnaces, further enhancing their appeal.

In conclusion, electric resistance furnaces offer a reliable, efficient, and environmentally friendly solution for heat treatment processes across a wide range of industries. With their precision temperature control, energy efficiency, and low maintenance requirements, these furnaces are poised to remain a cornerstone of industrial heating technology for years to come.