Scrap aluminum to aluminum rod process, aluminum rod solution

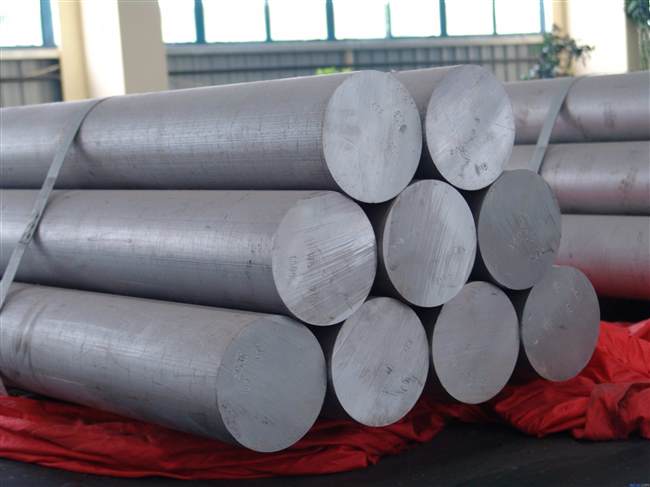

Aluminum Rod Production from Scrap Aluminum – Comprehensive Industrial Solutions

Recycling scrap aluminum into aluminum rods is not only economical but also environmentally responsible. It consumes only 5% of the energy required to produce primary aluminum. Dalian Jiuying Heavy Machine Co., Ltd. provides complete production line solutions, from scrap collection to final rod packaging, ensuring efficiency, quality, and sustainability.

Step 1: Collection & Sorting

Machines/Equipment:

- Conveyor belts: Transport scrap materials efficiently across the plant.

- Magnetic separators: Remove ferrous metals from aluminum scrap.

- Shredders: Reduce large aluminum scrap pieces to manageable sizes.

- Eddy current separators: Further segregate non-aluminum contaminants.

Efficient collection and sorting not only improve productivity but also enhance the quality of the final aluminum rods by reducing impurities from the beginning.

Step 2: Melting

Machines/Equipment:

- Reverberatory or rotary melting furnaces: Melt scrap aluminum efficiently and remove impurities.

Advanced temperature control ensures uniform melting and energy savings. Proper melting is essential for achieving high-quality aluminum rods suitable for industrial applications.

Step 3: Alloying

Machines/Equipment:

- Holding and dosing furnaces: Add alloying elements to achieve the desired composition for specific mechanical and electrical properties.

Custom alloying allows the production of rods tailored for electrical conductors, automotive components, or structural applications.

Step 4: Degassing & Impurity Removal

Machines/Equipment:

- Degassing units: Remove hydrogen and dissolved gases from molten aluminum using inert gases like nitrogen or argon.

- Ceramic foam filters: Eliminate solid impurities for a cleaner, more homogeneous melt.

These steps significantly improve the mechanical strength and surface quality of the final aluminum rods, ensuring they meet international standards.

Step 5: Casting

Machines/Equipment:

- Continuous casting machines: Form billets or logs from molten aluminum as precursor forms for extrusion.

- Cooling systems: Rapidly solidify cast aluminum for consistent microstructure.

Continuous casting increases production efficiency and produces aluminum billets with uniform properties, reducing downstream defects.

Step 6: Extrusion

Machines/Equipment:

- Extrusion presses: Heat and push aluminum billets through dies to produce rods with precise cross-sectional profiles.

- Run-out tables: Support rods as they exit the press, preventing deformation.

- Quenching systems: Rapidly cool rods to enhance mechanical properties.

Our extrusion technology ensures tight dimensional tolerances, smooth surfaces, and excellent mechanical performance suitable for high-end applications.

Step 7: Aging (Optional)

Machines/Equipment:

- Aging ovens: Heat treat extruded rods to further enhance mechanical properties such as strength and hardness.

Aging is especially important for aluminum rods used in structural and aerospace applications.

Step 8: Cutting & Finishing

Machines/Equipment:

- Cutting machines: Cut rods to specific lengths according to customer requirements.

- Polishing machines: Provide smooth surface finish when required.

Custom cutting and finishing ensure rods meet client specifications and are ready for immediate use in production lines.

Industrial Applications & Case Examples

Aluminum rods produced from scrap are widely used in:

- Electrical wiring and conductors

- Automotive and aerospace components

- Construction and building materials

- Industrial machinery and equipment

Our clients across Asia, Europe, and North America have successfully implemented our aluminum rod production lines to increase efficiency, reduce waste, and improve product quality.

Quality Control & Sustainability

Dalian Jiuying Heavy Machine Co., Ltd. maintains strict quality control across every stage of production. Our processes comply with international standards, ensuring high-strength, defect-free aluminum rods. Recycling scrap aluminum conserves energy and reduces environmental impact, making our production lines both economical and sustainable.

Why Choose Dalian Jiuying?

- Complete aluminum rod production line solutions, including design, equipment, installation, and commissioning

- Energy-efficient and environmentally friendly technology

- Technical support and operator training for all clients

- Global service network for timely maintenance and spare parts supply

- Customized solutions to meet specific industry requirements

Interested in Our Products?

Every project is unique. Our experts provide tailored solutions and direct support to help you optimize your aluminum rod production line.

Why Send an Inquiry?

- Personalized Assistance: Solutions tailored for your production needs.

- Quick Response: Dedicated team replies within 24 hours.

- Expert Advice: Industry insights and recommendations from experienced engineers.