Aluminum Extrusion Equipment: Process, Benefits, and Manufacturing Procedure

The utilization of aluminum extrusion equipment in product design and manufacturing has experienced a substantial surge in recent decades.

As per a recent report from Technavio, the global market for aluminum extrusion is poised for accelerated growth between 2019-2023, with a Compound Annual Growth Rate (CAGR) of nearly 4%.

Perhaps you're familiar with this manufacturing process and are curious about its workings.

Today, we'll delve into what aluminum extrusion entails, the advantages it presents, and the sequential stages of the extrusion process.

We'll commence with the fundamental query.

Table of Contents

- What is Aluminum Extrusion?

- What Shapes Can be Extruded?

- Aluminum Extrusion Process in 10 Steps

- What Follows? Heat Treatment, Finishing, and Fabrication

- Summary: Aluminum Extrusion is an Essential Manufacturing Technique

- Aluminum Extrusion Equipment Design Guide

What is Aluminum Extrusion?

Aluminum extrusion involves the propulsion of aluminum alloy material through a die with a specified cross-sectional profile.

Toothpaste emerging from a tube can serve as an analogy for aluminum extrusion.

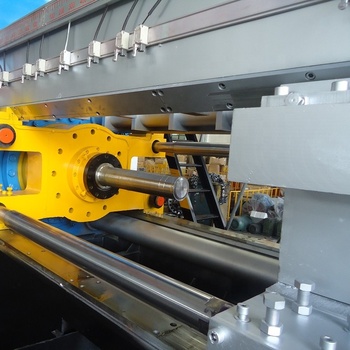

A robust ram propels the aluminum through the die, shaping it accordingly, as it emerges from the die opening.

At its core, the aluminum extrusion process is relatively straightforward to grasp.

The force applied can be likened to squeezing toothpaste from a tube.

As pressure is applied, the aluminum adopts the shape of the die's opening, similar to how toothpaste conforms to the tube's shape upon squeezing.

What Shapes Can be Extruded?

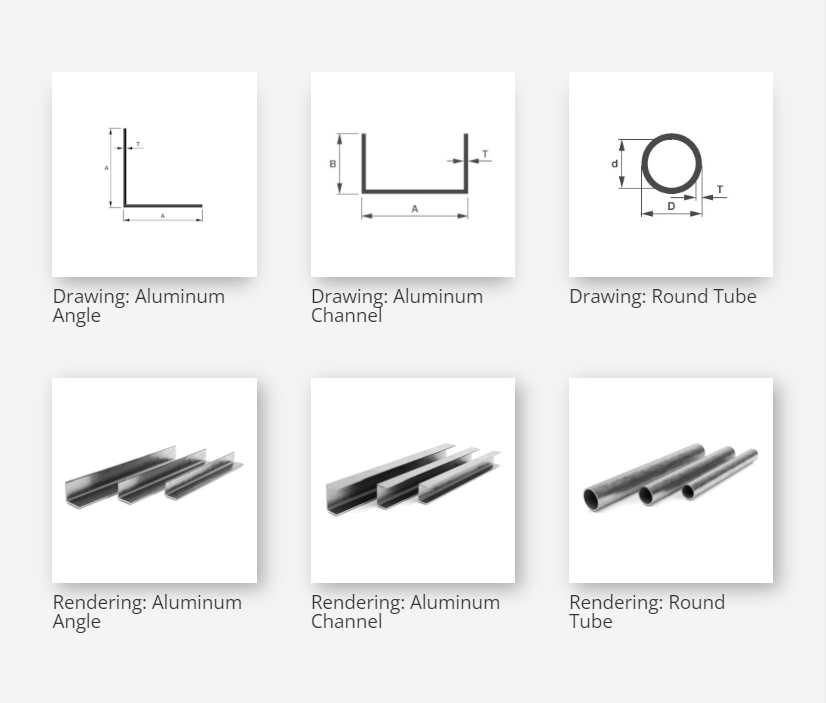

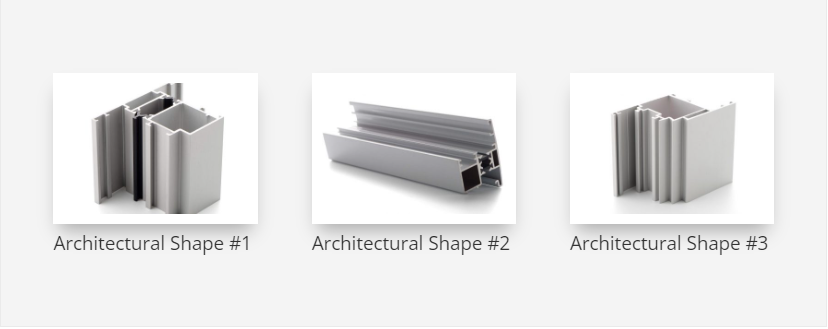

Aluminum extruded shapes fall into three primary categories:

- Solid, devoid of enclosed voids or openings (e.g., rod, beam, or angle).

- Hollow, featuring one or more voids (e.g., square or rectangular tube).

- Semi-hollow, with a partially enclosed void (e.g., a "C" channel with a narrow gap).

Aluminum Extrusion Process in 10 Steps

The extrusion process is delineated into ten steps. Let's examine them.

- The Extrusion Die is Prepared and Moved to the Extrusion Press

- An Aluminum Billet is Preheated Before Extrusion

- The Billet is Transferred to the Extrusion Press

- The Ram Pushes the Billet Material into the Container

- The Extruded Material Emerges Through the Die

- Extrusions are Guided Along the Runout Table and Quenched

- Extrusions are Sheared to Table Length

- Extrusions are Cooled to Room Temperature

- Extrusions are Moved to the Stretcher and Stretched into Alignment

Extrusions are Moved to the Finish Saw and Cut to Length

What Follows? Heat Treatment, Finishing, and Fabrication

Upon completion of extrusion, profiles can undergo heat treatment to augment their properties.

Subsequently, they can receive diverse surface finishes to enhance appearance and corrosion resistance, followed by fabrication operations to achieve final dimensions.

Summary: Aluminum Extrusion is an Essential Manufacturing Technique

Aluminum extrusion is pivotal for creating parts with specific cross-sectional profiles by propelling heated alloy material through a die.

Shapes can range from simple to complex, and the resulting profiles can undergo further treatments and fabrication to meet customer specifications.

To delve deeper into optimizing part design for the extrusion process, contact us!