Two Stage Coal Gasifier

The two-stage gas generator is currently the most mature equipment in the application of gas station projects in China.

Photos of

Detailed introduction

Description

A two-stage gas furnace is a set machine. electricity. The project of gasification integration, the two-stage furnace is mainly composed of a coal preparation section, electrical control, coal addition section, dry distillation section, gasification section, ash discharge section, and gasification agent preparation section. Different requirements and quality requirements for the overall design.

Working Principle

The upper-stage gas produced from the two-stage gasifier has a temperature of about 80~120°C and a calorific value of about 6688~7106KJ/Nm³ (1600~1700kcal/Nm³) to the electric tar collector to catch tar.

The hot gas in the lower section (the furnace outlet temperature is about 550~600°C), with a calorific value of about 5016~5434kJ/Nm³ (1200~1300kcal/Nm³), is forced to cool by the forced cooler and enters the indirect cooler at the same time as the upper section gas to cool separately.

Mix at the outlet of the gas cooler to the electric light oil catcher to remove light oil, residual tar, and dust. The treated cold and clean gas is pressurized by the gas pressurizer and delivered to the user.

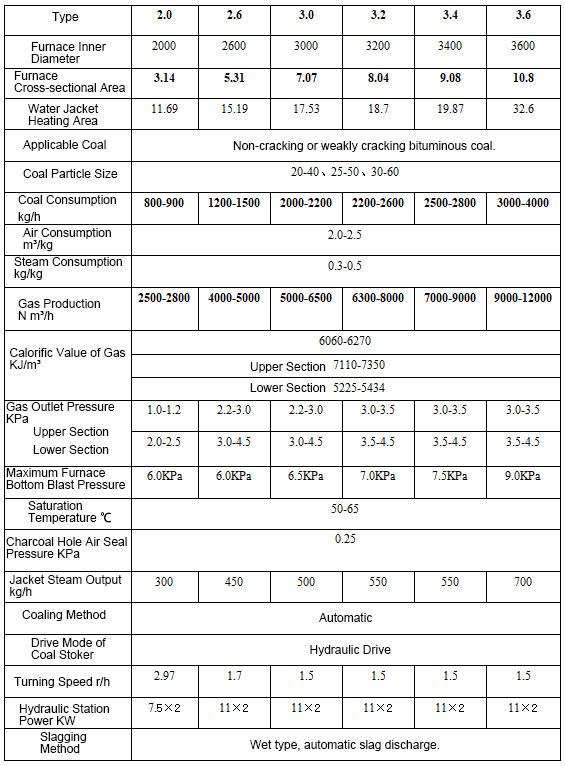

Main Technical Parameters