Coal Gas Furnace

A coal gasifier is a coal gas production facility that minimizes operational steps and reduces energy losses.

Photos of

Detailed introduction

In recent years, with advancements in science and technology, the energy-saving and environmental protection benefits, affordability, and excellent heating performance of the Coal Gas Furnace have been widely recognized by industrial users. This is particularly evident in industries like building ceramics, where the coal gasifier plays a crucial role in achieving efficient and sustainable production.

Currently, coal gasifiers are evolving towards miniaturization, simplification, environmental protection, and cost-efficiency. Modern designs emphasize on-site production and on-site usage to minimize operational processes and reduce energy loss, making the Coal Gas Furnace an indispensable tool for industries aiming to optimize performance while reducing environmental impact.

Working Principle

The gas generator is a device that uses coal as raw material to produce gas for use in gas equipment. The solid raw coal is fed from the top of the furnace and moves downward with the operation of the gas furnace.

When it meets the gasification agent (air, steam) entering from the bottom of the furnace, it is heated by the high-temperature gas in the fuel layer at the bottom of the furnace, and physical and chemical processes occur. The reaction produces crude gas. This crude gas (hot gas) can be directly used by combustion equipment after rough dust removal. This creates several zones in the gasifier, generally referred to as "layers".

Range of Work

The gas generator is a device that provides mixed generator gas for thermal processing workshops in machinery, metallurgy, building materials, light industry, chemical industry, refractory and other industries.

The gas generator is equipped with a single-bucket lifting coal loading machine, adopts a double-sealed bell jar coal feeding box for automatic coal feeding, and uses a wet ashtray for automatic slag removal. The grate transmission mechanism is all designed outside the furnace, which is reliable in operation and easy to install and maintain.

Why Choose Our Gasification Systems?

- Cost Efficiency: Save on operational costs with high gas production rates and optimized fuel consumption.

- Proven Technology: Employing world-class methodologies such as the Texaco Gasifier and Lurgi Gasification Process, our systems ensure reliability and efficiency.

- Versatility: From large-scale coal gasification power plants to smaller setups, our systems cater to diverse requirements.

- User-Friendly Operation: Options for DIY Coal Gasifier enthusiasts to industrial-grade installations.

Applications

Our gasification technology powers a variety of industries, including:

- Coal Gasification Power plants for sustainable energy production.

- Industrial processes requiring syngas derived from coal gasification.

- Petrochemical setups utilizing the Texaco Gasification Process for clean energy production.

Key Features of Our Gasification System

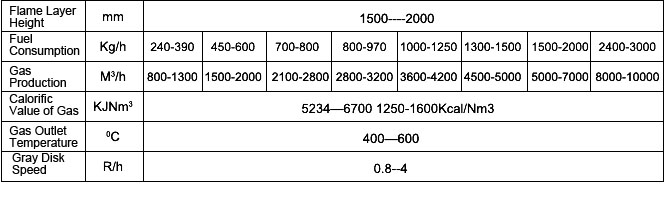

High Efficiency and Scalability:

- Flame Layer Height: Adjustable between 1500–2000 mm to optimize combustion.

- Fuel Consumption: Ranges from 240 to 3000 kg/h, accommodating various operational scales.

- Gas Production: Delivers 800 to 10,000 m³/h, tailored for industrial needs.

- Suitable for diverse applications, from coal gasification power plants to small-scale setups.

Customizable Specifications:

- Available in furnace diameters from Φ1.2 m to Φ3.2 m, with corresponding inner dimensions ranging from 1200 mm to 3200 mm.

- Sectional areas between 1.131 m² and 8.042 m² cater to varying production requirements.

- Compatible with anthracite, coke, and various types of bituminous coal.

Innovative Design:

- Incorporates Lurgi Coal Gasifier and Sasol Lurgi Gasifier technology for efficient energy conversion.

- Water jacket heating areas from 6.0 m² to 37 m² improve thermal stability and durability.

- Designed with pressures below 0.07 MPa, ensuring operational safety.

Eco-Friendly and Sustainable:

- Combines BGL Gasifier and Prenflo Gasifier principles to reduce harmful emissions.

- Supports advanced Texaco Gasification Process, achieving higher calorific value (5234–6700 KJ/Nm³) and cleaner gas output.

Main Technical Parameters