Aluminum Melting Furnace

An aluminum melting furnace is a new type of high-efficiency energy-saving furnace, which can well meet the requirements of the aluminum smelting process.

Photos of

Detailed introduction

About Product

Common aluminum melting furnaces typically come in rectangular or garden-shaped structural forms. A well-designed furnace structure plays a crucial role in enhancing heat transfer efficiency, thereby increasing melting capacity and reducing energy consumption. This improvement not only lowers operational costs but also minimizes material burning losses, leading to improved overall product quality. Additionally, such design enhancements contribute to a more efficient workflow, reducing labor intensity and creating better working conditions for operators.

These furnaces are particularly suited for intermittent operations, effectively handling the melting of both primary aluminum and recycled materials with optimal efficiency.

By focusing on optimizing furnace design, manufacturers can achieve significant improvements in production efficiency and product quality. Implementing advanced heat transfer technologies and insulation materials helps maximize thermal efficiency and minimize heat loss. This approach not only enhances the furnace's performance but also supports sustainable practices by reducing energy consumption and emissions. Overall, investing in a well-designed aluminum melting furnace ensures that manufacturers can meet production demands efficiently while maintaining high standards of operational efficiency and environmental responsibility.

Our Advantages

01

Advanced Design: Our furnaces are designed with advanced structural configurations that optimize heat transfer efficiency and enhance melting capacity.

02

Energy Efficiency: Utilization of innovative technologies and insulation materials to minimize heat loss and reduce energy consumption, leading to cost savings.

03

High-Quality Construction: Built from durable materials that ensure longevity and reliability in harsh industrial environments.

04

Customizable Options: Tailored solutions available to accommodate specific melting requirements, whether for primary aluminum or recycled materials.

05

Operational Efficiency: Designed for intermittent operations, maximizing productivity and operational flexibility.

06

Improved Product Quality: Enhanced control over melting processes results in superior product quality and consistency.

07

Environmental Responsibility: Commitment to sustainable practices, with furnaces designed to minimize emissions and support recycling efforts.

08

Comprehensive Support: Extensive after-sales service and technical support to ensure smooth installation, operation, and maintenance.

09

Global Standards: Compliance with international standards for safety, efficiency, and environmental impact.

10

Proven Performance: Trusted by industries worldwide for reliable performance and operational excellence.

Work Principle

The aluminum melting furnace operates on the principle of efficient biomass combustion and advanced heat transfer technologies. It utilizes renewable biomass pellet fuel, which is fed into the combustion chamber. Here, semi-gasification combined combustion occurs, where biomass pellets undergo partial gasification to enhance combustion efficiency. This process is complemented by tangential swirl air distribution, ensuring thorough mixing of air and fuel gases for optimal combustion conditions.

The furnace operates under micro-positive pressure, which prevents tempering and deflagration risks. This controlled environment maintains stable combustion conditions necessary for effective heat transfer to melt aluminum and its alloys. The design emphasizes emission control, resulting in minimal levels of soot, sulfur, and nitrogen emissions. This capability ensures compliance with stringent environmental regulations while supporting sustainable manufacturing practices.

Additionally, the furnace is equipped with features such as air-cooled protection and automatic feeding systems. These enhancements contribute to its safe and efficient operation, reducing manual intervention and enhancing overall productivity in industrial applications.

Features

01

Low-Cost Energy Source: Utilizes renewable biomass pellet fuel, ensuring economical operation costs.

02

Efficient Combustion: Incorporates semi-gasification combined combustion with tangential swirl air distribution for optimized efficiency. Achieves a burnout rate exceeding 98% through low-temperature stage combustion.

03

Micro-Positive Pressure: Operates under micro-positive pressure conditions, eliminating tempering and deflagration risks.

04

Environmentally Friendly: Ensures low emissions of soot, sulfur, and nitrogen, meeting stringent environmental regulations.

05

User-Friendly Design: Features air-cooled protection for enhanced safety, simple refitting capabilities, automatic feeding system for convenience, and straightforward operation.

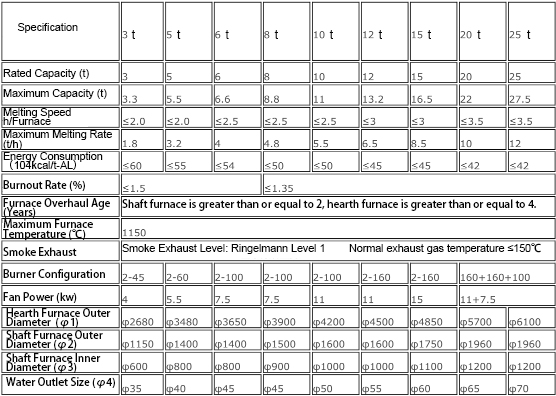

Main Technical Parameters

Main Application Fields

The aluminum melting furnace is widely used across industries such as foundries, recycling facilities, die casting, extrusion plants, and alloy production. It efficiently melts aluminum and its alloys, crucial for producing castings, recycling scrap aluminum, and manufacturing profiles and components used in automotive, aerospace, and construction sectors. Its ability to control emissions and ensure safe, efficient operation makes it essential for maintaining high standards of quality and sustainability in industrial processes worldwide.

Why Choose Us

Our aluminum melting furnaces are backed by certifications that validate their adherence to international standards for quality, safety, and environmental management. These certifications include ISO 9001 for quality management systems, ISO 14001 for environmental management, and OHSAS 18001 or ISO 45001 for occupational health and safety. These endorsements underscore our commitment to delivering reliable and environmentally responsible solutions for industrial melting applications.

Contact Us

Contact: Mr. Liu (manager)

Whatsapp/Mob/Wechat: 008613394110095

Email: [email protected]

Website: www.aluextrusionpress.com

Address: 20# Ganwang Street, Dalian City, China