Aluminum Extrusion Press

An aluminum profile extrusion machine is a kind of equipment used to produce aluminum profile alloy.

Photos of

Detailed introduction

Dalian Jiuying Machinery Equipment Co., Ltd., established in 2015, excels in providing state-of-the-art extrusion equipment for aluminum and copper profiles. Serving a variety of sectors such as automotive, aerospace, and construction, we pride ourselves on our strong R&D and customization capabilities. Our high-performance extruders have garnered trust from clients worldwide, including key markets in the US, Italy, and Russia. With a commitment to innovation and customer satisfaction, Jiuying aims to forge enduring, mutually beneficial relationships. For premier extrusion solutions, look no further than Jiuying.

Why Choose Us

01|Language advantage

The company has dedicated English, Russian and Spanish foreign trade personnel to solve most communication problems

02|Price advantage

The company connects with many domestic factories and can select suitable products according to user needs, which is more cost-effective.

03|Customized Solutions

We offer robust R&D and product development capabilities, providing tailored production services to meet the unique needs of each customer.

Product description

Description

There are two kinds of aluminum extrusion press, which are double-action extruder, and positive and negative extruder series, this equipment can be used to produce and extrude all kinds of construction, rail transit, auto parts, aviation, and other types of profiles.

Features

Structure

The machine has a four-column horizontal structure with a top-mounted oil tank. Its structure is compact and easy to assemble or disassemble.

Extrusion Process

There are two extrusion processes: following needles and fixed needles. Our machine can meet the extrusion requirements of different pipe diameters.

Electronic Component

We use PLC control and can do man-machine interface real-time monitoring.

Hydraulic System

Hydraulic system adopts large flow plug valve, stable performance, large flow, and low-temperature rise.

Host Part

The ingeniously inverted oil cylinder of the shearing mechanism offers stability and prolonged durability, enhancing the overall reliability of the machine.

Locate Mode

The movable beam adopts four points positioning, and the center can be adjusted. It is convenient, safe, and rapid.

Contact Us

Ready to revolutionize your aluminum extrusion capabilities? Contact us today to explore how our advanced aluminum profile extrusion line machines can elevate your manufacturing processes. Our team of experts is poised to assist you in selecting the perfect solution tailored to your specific requirements. Don't miss out on the opportunity to unlock unparalleled efficiency and precision in aluminum profile extrusion—reach out to us now!

Whatsapp/Mob/Wechat: 008613394110095

Email: [email protected]

Website: www.aluextrusionpress.com

Working Principle

The working principle of an aluminium extrusion press is elegantly simple yet remarkably efficient. It operates by forcing molten aluminium through a shaped die, thereby creating the desired profile. This process is facilitated by immense pressure generated within the press, typically through hydraulic systems, ensuring accurate and consistent results.

Main Application Scenarios for Aluminium Profile Extrusion Line Machines

The range of work for aluminum extrusion machines is broad, encompassing various industries and applications. Here are some key areas and industries where these machines are commonly utilized:

Automotive

Industry

Components and Parts: Production of lightweight, durable parts such as chassis, frames, engine components, and heat exchangers.

Structural Elements: Creation of structural components that contribute to the overall strength and safety of vehicles.

Aerospace Industry

Aircraft Structures: Manufacturing of critical aircraft components like wing spars, fuselage sections, and landing gear parts.

Interior Elements: Production of cabin components, seat frames, and other interior fittings that require precision and strength.

Electrical and Electronics Industry:

Heat Sinks: Manufacturing of heat sinks and cooling elements used in electronic devices to dissipate heat efficiently.

Enclosures and Casings: Production of enclosures, housings, and casings for electrical equipment and consumer electronics.

Renewable Energy

Solar Panel Frames: Creation of frames and supports for solar panels, ensuring durability and precision.

Wind Turbine Components: Production of various structural elements for wind turbines, including support structures and nacelle frames.

Transportation:

Rail and Marine: Manufacturing of components for railcars, ships, and other transport vehicles, focusing on lightweight and corrosion-resistant properties.

Bicycle Frames: Production of lightweight and strong frames for bicycles and other personal transportation devices.

Industrial Applications

Machinery and Equipment: Production of structural components for industrial machinery and equipment.

Pneumatic and Hydraulic Systems: Creation of profiles used in pneumatic and hydraulic systems, including cylinders and actuators.

Consumer Goods:

Furniture and Appliances: Manufacturing of structural and decorative elements for furniture, household appliances, and fixtures.

Sports Equipment: Production of lightweight and durable components for sports equipment, such as ski poles, rackets, and fitness machines.

Custom and Specialized Applications

Tailored Solutions: Development of custom extrusions for unique and specialized applications across various industries, driven by specific client requirements.

The versatility and precision of aluminum extrusion machines make them indispensable in producing a wide range of high-quality, complex profiles tailored to the specific needs of diverse industries.

Product Parameters

| Model | Unit | JY-630 | JY-800 | JY-1000 | JY-1250 | JY-1630 | JY-1800 | JY-2200 | JY-2500 |

| Rated Extrusion Force | KN | 6300 | 8000 | 10000 | 12500 | 16300 | 18000 | 22000 | 25000 |

| UST | 700 | 880 | 1100 | 1350 | 1800 | 2000 | 2420 | 2750 | |

| Fixed Work Stress | MPa | 21 | 21 | 21 | 21 | 21 | 21 | 21 | 21 |

| Locking Force | KN | 633 | 633 | 800 | 800 | 1586 | 1586 | 1586 | 1586 |

| Perforation Force (Double Action Extrusion Machine) | KN | 1030 | 1030 | 1293 | 1293 | 2500 | 2800 | 3000 | 3500 |

| Extruding Speed | mm/s | 40 | 50 | 40 | 50 | 40 | 40 | 40 | 40 |

| Extrusion Cylinder Preheating Power (Single Per Rod × Number) | KW | 1.2×12 | 1.5×12 | 2×12 | 2×12 | 3×12 | 3×12 | 3×15 | 3.5×15 |

| Main Motor Power | KW | 75×3 | 132×3 | 132×3 | 132×4 | 132×5 | 132×6 | 132×7 | 132×8 |

| Extrusion Barrel Inner Hole Size Range (Aperture x Length) | mm | φ85-φ115×500 | φ105-φ135×550 | φ125-φ135×600 | φ135-φ165×650 | φ155-φ205×750 | φ175-φ225×800 | φ195-φ245×900 | φ205-φ265×1000 |

| Center Height of Main Unit | mm | 850 | 1040 | 1100 | 1180 | 1500 | 1500 | 1650 | 1850 |

| Dimensions of Single-action Host (L × W × H) | m | 6.8×2.3×2.8 | 9.2×2.3×3.1 | 10×2.4×3.3 | 11.5×2.5×3.4 | 13.5×4.2×4.1 | 14.5×4.2×4.1 | 15.5×4.7×4.5 | 18×5×4.8 |

| Dimensions of Dual-action Host (length × width × height) | m | 7.8×2.3×2.8 | 10.5×2.3×3.1 | 11.8×2.4×3.3 | 13.3×2.5×3.4 | 15.5×4.2×4.1 | 16.5×4.2×4.1 | 18.5×4.7×4.5 | 20×5×4.8 |

Similar products

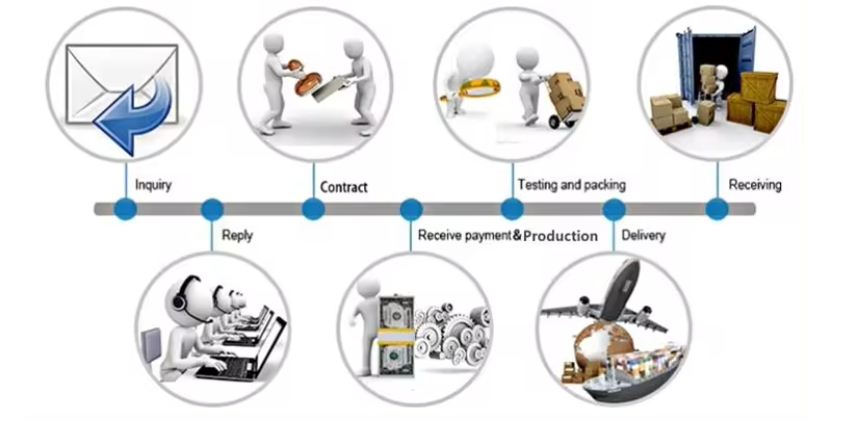

How to Enquire

Founded in 2015, Dalian Jiuying Machinery Equipment Co., Ltd. specializes in cutting-edge extrusion equipment for aluminum and copper profiles. Our products cater to diverse industries including automotive, aerospace, and construction. Renowned for our robust R&D and customization capabilities, our high-performance extruders are trusted by clients globally, with significant markets in the US, Italy, and Russia. At Jiuying, we are dedicated to innovation and customer satisfaction, aiming to build long-term, mutually beneficial partnerships. Choose Jiuying for top-tier extrusion solutions.

Whatsapp/Mob/Wechat: 008613394110095

Email: [email protected]

Website: www.aluextrusionpress.com

Common Issues and Solutions for Aluminum Extrusion Press

Aluminum extrusion presses are complex machines that can encounter a variety of issues during operation. Here are some common problems and their solutions:

1. Surface Defects

Issues:

- Die Lines: Scratches or lines on the surface of the extruded profile caused by die imperfections.

- Tearing: Occurs when the material is not flowing smoothly through the die.

Solutions:

- Die Maintenance: Regular inspection and maintenance of dies to ensure smooth surfaces.

- Lubrication: Proper lubrication of the die and billet to reduce friction.

- Adjustments: Fine-tuning the extrusion parameters such as temperature, speed, and pressure.

2. Dimensional Inconsistencies

Issues:

- Thickness Variation: Inconsistent thickness of the extruded profile.

- Out-of-Tolerance Profiles: Profiles not meeting specified dimensions.

Solutions:

- Die Correction: Ensure the die is properly designed and manufactured.

- Process Control: Maintain consistent temperatures and extrusion speeds.

- Calibration: Regularly calibrate and adjust the press settings.

3. Overheating

Issues:

- Billet Overheating: Causes poor material flow and defects.

- Press Overheating: Leads to excessive wear and tear on the machinery.

Solutions:

- Temperature Monitoring: Use thermal sensors to monitor and control the temperature of the billet and the press.

- Cooling Systems: Implement effective cooling systems for the billet and the press components.

- Heat Management: Ensure proper heat management techniques are in place to dissipate excess heat.

4. Billet Defects

Issues:

- Contaminants: Impurities in the billet can cause surface defects and weak spots.

- Inhomogeneity: Inconsistent material properties within the billet.

Solutions:

- Material Quality Control: Use high-quality billets with minimal impurities.

- Homogenization: Ensure billets are properly homogenized before extrusion.

- Inspection: Regularly inspect billets for defects before use.

5. Mechanical Failures

Issues:

- Component Wear and Tear: Bearings, seals, and other components wearing out over time.

- Hydraulic Leaks: Leaks in the hydraulic system affecting pressure and performance.

Solutions:

- Regular Maintenance: Implement a preventive maintenance schedule to replace worn components.

- Hydraulic System Checks: Regularly inspect and maintain the hydraulic system to prevent leaks.

- Spare Parts: Keep an inventory of critical spare parts for quick replacement.

6. Poor Extrusion Quality

Issues:

- Non-Uniform Flow: Material flow through the die is not uniform, leading to defects.

- Inconsistent Cooling: Uneven cooling can cause warping and residual stresses.

Solutions:

- Die Design: Ensure the die is properly designed to allow uniform material flow.

- Extrusion Speed: Optimize the extrusion speed to balance material flow and cooling rates.

- Cooling System Optimization: Use controlled cooling systems to ensure even cooling of the extruded profile.

7. Alignment Issues

Issues:

- Misalignment: Misalignment of the press components leading to uneven pressure and defects.

Solutions:

- Alignment Checks: Regularly check and adjust the alignment of the press components.

- Precision Components: Use high-precision components to maintain alignment.

8. Die Breakage

Issues:

- Die Cracking: Dies may crack under excessive pressure or due to manufacturing defects.

Solutions:

- Proper Die Handling: Handle dies with care to prevent damage.

- Pressure Control: Ensure the pressure applied is within the safe limits for the die.

- Quality Dies: Use high-quality dies manufactured to withstand the pressures of extrusion.

By addressing these common issues with proactive maintenance, quality control, and process optimization, the efficiency and output quality of aluminum extrusion presses can be significantly improved.

Aluminum Extrusion Press Maintenance

Maintaining an aluminum extrusion press is essential to ensure its longevity, efficiency, and the quality of the extruded products. Here are key aspects and steps involved in the maintenance of an aluminum extrusion press:

1. Regular Inspection

- Visual Inspection: Regularly inspect the press for any visible signs of wear, damage, or misalignment.

- Component Check: Inspect critical components such as dies, rams, containers, and hydraulic systems for any wear and tear.

2. Lubrication

- Lubricate Moving Parts: Ensure that all moving parts are properly lubricated to reduce friction and prevent wear.

- Lubricant Levels: Regularly check and maintain the levels of lubricants in the system.

3. Cleaning

- Clean the Press: Keep the press clean from any debris, aluminum shavings, and other contaminants that can interfere with its operation.

- Die Cleaning: Ensure that dies are clean and free from any buildup that can affect the quality of the extrusions.

4. Hydraulic System Maintenance

- Leak Check: Regularly inspect the hydraulic system for leaks and repair any found immediately.

- Fluid Levels: Ensure that hydraulic fluid levels are maintained within recommended limits.

- Filter Replacement: Replace hydraulic filters regularly to ensure clean fluid circulation.

5. Component Replacement

- Wear Parts: Replace parts that are subject to wear, such as seals, bearings, and bushings, on a regular schedule.

- Spare Parts Inventory: Maintain an inventory of critical spare parts to minimize downtime during repairs.

6. Calibration and Alignment

- Regular Calibration: Calibrate the press regularly to ensure accurate pressure, temperature, and extrusion speed settings.

- Alignment Check: Regularly check and adjust the alignment of the press components to ensure even pressure distribution.

7. Temperature Control

- Monitor Temperatures: Use sensors to monitor the temperature of the billet, die, and press components.

- Cooling Systems: Ensure cooling systems are functioning properly to prevent overheating.

8. Die Maintenance

- Die Inspection: Regularly inspect dies for wear and damage.

- Die Polishing: Polish dies to maintain a smooth surface, which helps in producing high-quality extrusions.

- Die Storage: Store dies properly to prevent damage when not in use.

9. Safety Checks

- Safety Devices: Ensure all safety devices and emergency stops are functioning properly.

- Operator Training: Regularly train operators on safety protocols and proper machine handling.

10. Documentation

- Maintenance Logs: Keep detailed logs of all maintenance activities, inspections, and repairs.

- Service Records: Maintain records of all service and replacement activities to track the history of the press.

11. Preventive Maintenance Schedule

- Daily Checks: Basic inspections and lubrication checks.

- Weekly Maintenance: More detailed inspections, cleaning, and lubrication tasks.

- Monthly Maintenance: Comprehensive checks, including hydraulic system inspection and calibration.

- Quarterly Maintenance: Thorough inspection and replacement of wear parts, detailed cleaning, and alignment checks.

- Annual Maintenance: Complete overhaul of the press, including major component replacements, system upgrades, and extensive calibration.

By following these maintenance practices, you can ensure the efficient and reliable operation of an aluminum extrusion press, minimize downtime, and extend the life of the equipment.

How much does an aluminium extrusion tool cost?

The cost of an aluminum extrusion tool varies based on several factors including the complexity of the profile, the size of the die, and additional customizations. Typically, the cost of an aluminum extrusion die can range from $2,000 to $10,000 or more.

Simple, solid dies that produce basic shapes like rods or beams are generally less expensive. These might cost around $2,000 to $5,000. On the other hand, more complex dies, such as those used for creating hollow profiles with multiple voids, can be significantly more expensive, often exceeding $10,000 (Gabrian) (Sunrise Metal).

Other factors influencing the cost include the type of aluminum alloy used, the required surface finish, and the production volume. Extruders may offer lower costs per unit for larger orders due to economies of scale (Gabrian) (Momentum Extrusions).

For further details and to get a more accurate estimate tailored to your specific needs, it’s advisable to request a quote from manufacturers like Gabrian International or Superior Metal Shapes. You can also find comprehensive guides on aluminum extrusion processes and costs on their websites:

Frequently Asked Questions (FAQ) for Aluminum Extrusion Press

1. What makes Dalian Jiuying Machinery Equipment Co., Ltd. aluminum extrusion presses stand out from competitors?

- Dalian Jiuying Machinery Equipment Co., Ltd. prioritizes cutting-edge technology, precision engineering, and a commitment to quality assurance. Our presses are designed to exceed industry standards, offering unparalleled performance and reliability.

2. How can I be sure that a Dalian Jiuying Machinery Equipment Co., Ltd. aluminum extrusion press meets my production needs?

- Our expert team will work closely with you to assess your specific requirements, ensuring that the press you choose aligns perfectly with your production goals. We provide comprehensive consultations and customized solutions tailored to your needs.

3. What after-sales support and services does Dalian Jiuying Machinery Equipment Co., Ltd. offer?

- Dalian Jiuying Machinery Equipment Co., Ltd. is dedicated to providing exceptional after-sales support, including technical assistance, spare parts availability, maintenance contracts, and comprehensive training programs. Our goal is to maximize the uptime and efficiency of your operations.

4. Can I expect innovative features and advanced technology in Dalian Jiuying Machinery Equipment Co., Ltd. extrusion presses?

- Absolutely! Innovation is at the core of everything we do at Dalian Jiuying Machinery Equipment Co., Ltd. Our presses incorporate the latest technological advancements, including automation, precision control systems, and energy-efficient solutions, to optimize your production processes.

5. How does Dalian Jiuying Machinery Equipment Co., Ltd. ensure regulatory compliance and safety standards?

- Dalian Jiuying Machinery Equipment Co., Ltd. is committed to upholding the highest standards of safety and regulatory compliance. Our presses undergo rigorous testing and certification processes to ensure compliance with industry regulations, providing you with peace of mind and confidence in your operations.

6. What warranty coverage do Dalian Jiuying Machinery Equipment Co., Ltd. aluminum extrusion presses offer?

- We stand behind the quality and reliability of our products with comprehensive warranty coverage. Our warranty policies are designed to protect your investment and provide you with added assurance of our commitment to excellence.

7. Can I receive references or testimonials from other satisfied Dalian Jiuying Machinery Equipment Co., Ltd. customers?

- Absolutely! We are proud of the relationships we've built with our customers and would be happy to provide references or testimonials upon request. Hear directly from our satisfied customers about their experiences with Dalian Jiuying Machinery Equipment Co., Ltd. extrusion presses.

8. How does Dalian Jiuying Machinery Equipment Co., Ltd. ensure affordability and value for customers?

- Dalian Jiuying Machinery Equipment Co., Ltd. is dedicated to delivering exceptional value to our customers. We offer competitive pricing without compromising on quality, ensuring that you receive the best possible return on your investment in our aluminum extrusion presses.

9. What training opportunities does Dalian Jiuying Machinery Equipment Co., Ltd. provide for operators and maintenance staff?

- Dalian Jiuying Machinery Equipment Co., Ltd. offers comprehensive training programs to ensure that your operators and maintenance staff are equipped with the knowledge and skills they need to operate and maintain our extrusion presses safely and effectively.

10. How can I get started with selecting the right Dalian Jiuying Machinery Equipment Co., Ltd. aluminum extrusion press for my needs?

- Contact us today to speak with one of our knowledgeable representatives and begin the process of choosing the perfect aluminum extrusion press from Dalian Jiuying Machinery Equipment Co., Ltd. We're here to support you every step of the way!