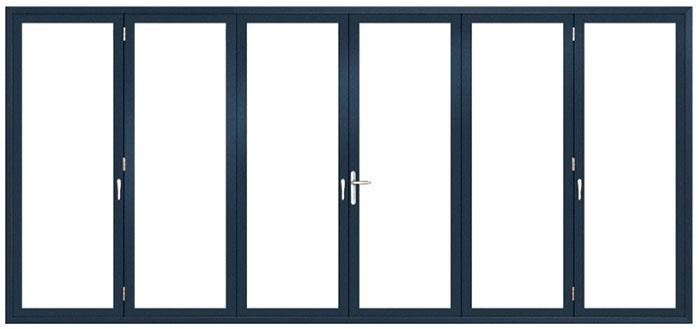

630t Aluminum Extrusion Press for Aluminum Door and Window Manufacturing

630t Aluminum Extrusion Press: The Ultimate Solution for Aluminum Door and Window Manufacturing Introducing our state-of-the-art 630t Aluminum Extrusion Press, engineered specifically to cater to the rigorous demands of aluminum door and window production. At the heart of countless successful manufacturing operations, our machine boasts unparalleled precision, efficiency, and reliability.

Photos of

Detailed introduction

630t Aluminum Extrusion Press: The Ultimate Solution for Aluminum Door and Window Manufacturing

Introducing our state-of-the-art 630t Aluminum Extrusion Press, engineered specifically to cater to the rigorous demands of aluminum door and window production. At the heart of countless successful manufacturing operations, our machine boasts unparalleled precision, efficiency, and reliability.

Key Features:

Precision Performance: Designed to handle aluminum bars up to 90mm in diameter, our press guarantees an unmatched level of precision. Every extrusion showcases meticulous attention to detail, ensuring your end products meet the highest standards of quality.

Robust and Durable: With a formidable 630-tonne capacity, this machine is constructed with the latest metallurgical advancements. This ensures durability, even under the most challenging production conditions.

User-Friendly Operations: Modern computer control systems provide ease of operation, allowing manufacturers to achieve optimal results with minimal effort. The interface is intuitive, and the automation capabilities significantly reduce manual errors.

Efficient Heating and Cooling Systems: The integrated heating system ensures uniform pre-heating of aluminum bars. Post-extrusion, the rapid cooling mechanism ensures that the extruded profiles retain their desired shape, essential for high-quality door and window frames.

Safety and Maintenance: Our commitment to safety is paramount. The 630t Aluminum Extrusion Press comes equipped with multiple safety features, ensuring operators are protected at all times. Furthermore, the machine is designed for easy maintenance, ensuring minimal downtime and maximizing productivity.

Why Choose Our 630t Aluminum Extrusion Press?

✓ Cost-Effective Production: Reduced wastage and increased efficiency mean a tangible reduction in manufacturing costs.

✓ Consistency: Deliver uniform products batch after batch, fostering trust and reliability among your clientele.

✓ Technical Support: Our team of experts is always on standby to assist you. From installation to troubleshooting, we’ve got you covered.

✓ Eco-friendly: Designed with the environment in mind, our machine ensures reduced energy consumption without compromising on performance.

630t Aluminum Extrusion Press: Revolutionizing Aluminum Door and Window Manufacturing

The creation of high-quality aluminum doors and windows hinges on precision machinery, and at the forefront of this revolution is the 630t Aluminum Extrusion Press. Understanding the journey from raw aluminum to a finished product helps in appreciating the vital role this machinery plays.

1. Raw Material Preparation:

Aluminum Billets: The journey starts with raw aluminum, typically in the form of billets, which are cylindrical bars of aluminum. For our 630t Extrusion Press, the billets can be up to 90mm in diameter.

2. Heating the Billet:

Billet Heater: Before extrusion, the aluminum billets are preheated to around 400-500°C. This softens the metal, making it easier to shape. An integrated heating system ensures that the billets reach an optimal and uniform temperature throughout.

3. Extrusion Process:

630t Aluminum Extrusion Press: This is where the magic happens. The preheated billet is placed in the press's container. Under the force of the press, it is pushed through a die, a tool that defines the profile's shape (in this case, parts for doors and windows). The 630-tonne capacity ensures that even the most intricate profiles can be produced with razor-sharp precision.

4. Cooling the Extruded Profile:

Cooling Table: After emerging from the die, the extruded aluminum profile is rapidly cooled, solidifying its shape. It's essential that this cooling process is both swift and even to prevent any warping or deformation.

5. Cutting and Further Processing:

Sawing Machines: The long extruded sections are then cut to desired lengths using precision saws. This ensures that every piece, whether for a door frame or window sill, is consistent and to spec.

Aging Ovens: Sometimes, to increase the strength and hardness of the profiles, they are subjected to heat treatment in aging ovens.

6. Surface Finishing:

Anodizing or Powder Coating Machines: To improve durability and aesthetics, the aluminum profiles may undergo surface treatments. Anodizing gives a protective oxide layer, while powder coating can provide various colors and finishes.

7. Assembly:

Assembly Stations: This is where the individual extruded profiles come together. They're assembled into door and window frames, ready for installation. Depending on the design, gaskets, hinges, and other accessories are also added.

Why 630t Aluminum Extrusion Press is Essential:

Precision: The press ensures that every extrusion is accurate, leading to components that fit together perfectly during assembly.

Speed & Efficiency: With the 630t capacity, large batches of profiles can be produced in a shorter time, meeting high production demands.

Versatility: Different dies can be used, allowing for a wide range of door and window designs to be manufactured on the same machine.

In summary, the 630t Aluminum Extrusion Press stands as the backbone of modern aluminum door and window manufacturing. With this machine, producers are assured of quality, precision, and efficiency, attributes that are pivotal in today's competitive market.

Make the Right Investment for Your Business!

In the world of aluminum door and window manufacturing, the right machinery can propel your business to new heights. Our 630t Aluminum Extrusion Press is not just a machine; it's a promise of quality, efficiency, and unparalleled performance.

Don’t miss out on this game-changing equipment. Elevate your production capabilities and stand out in the market.

Ready to transform your manufacturing operations? Contact us today for inquiries and get a personalized quote. Your next big success story starts here!