Aluminum Melting and Holding Furnace

An aluminum liquid electric insulation furnace is a special equipment for aluminum alloy solution insulation.

Photos of

Detailed introduction

The aluminum melting and holding furnace is designed for the efficient melting and preservation of aluminum alloy melts. Its versatile design caters to processes such as degassing before aluminum casting, alloy preparation, structural uniformity, and temperature adjustments. This furnace ensures precise and safe operations, making it ideal for modern die-casting and casting applications.

Key Features and Advantages

High-Quality Molten Aluminum

The aluminium holding furnace ensures a uniform composition and accurate temperature of the molten aluminum, resulting in lower hydrogen content and improved casting quality.Flexible Production Organization

The crucible can be easily replaced, allowing for the production of various aluminum alloys without contamination. This makes the furnace adaptable to diverse casting needs.Reduced Aluminum Burn Loss

By heating aluminum through the crucible's heat conduction, the furnace minimizes localized high temperatures, thereby reducing oxidation losses. The burn loss of aluminum is kept under 1.2%, ensuring material efficiency.Enhanced Safety Design

The furnace bottom is constructed with high-strength casting material and includes a water leakage system. If the crucible fails, the molten aluminum safely exits through this mechanism, protecting the furnace body and operator safety.Efficient Temperature Control

A series-loop temperature control system prevents overheating and ensures optimal heating efficiency for both the furnace and molten aluminum.Advanced Thermocouple Protection

The thermocouple protection tube is made of silicon nitride, offering excellent thermal conductivity, corrosion resistance, and durability. This allows accurate temperature measurements of molten aluminum, with a service life exceeding two years.Comprehensive Safety Alarms

Multiple safety mechanisms, such as over-temperature alarms for aluminum liquid and the furnace cavity, and crucible leakage alarms, provide reliable operational security.

Energy Options

The aluminum holding furnace supports both electricity and natural gas as energy sources, allowing flexibility to match your facility's infrastructure.

Applications

This melting and holding furnace is particularly suited for aluminum die-casting and casting operations. Its precise control and minimal material waste make it an excellent choice for businesses focused on quality and efficiency.

Why Choose Our Aluminum Holding Furnace?

- Achieve uniform molten aluminum with low hydrogen content.

- Reduce material loss and improve operational safety.

- Easily replace crucibles to support varied production needs.

- Adapt energy sources (electricity or natural gas) to your preferences.

Invest in this holding furnace for casting to boost your productivity, ensure consistent quality, and minimize costs for your aluminum casting operations.

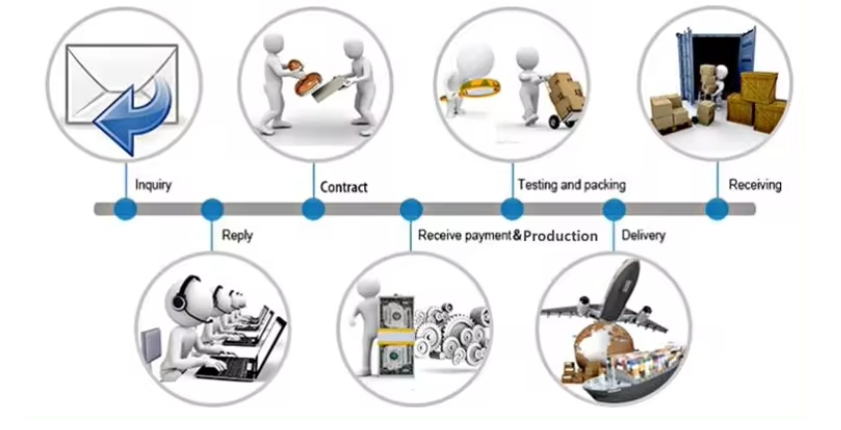

How to Enquire

Founded in 2015, Dalian Jiuying Machinery Equipment Co., Ltd. specializes in cutting-edge extrusion equipment for aluminum and copper profiles. Our products cater to diverse industries including automotive, aerospace, and construction. Renowned for our robust R&D and customization capabilities, our high-performance extruders are trusted by clients globally, with significant markets in the US, Italy, and Russia. At Jiuying, we are dedicated to innovation and customer satisfaction, aiming to build long-term, mutually beneficial partnerships. Choose Jiuying for top-tier extrusion solutions.

Whatsapp/Mob/Wechat: 008613394110095 Email: [email protected] Website: www.aluextrusionpress.com

Aluminum Melting and Holding Furnace – FAQs

1. What is the main purpose of the aluminum holding furnace?

The furnace is designed to melt and hold aluminum alloy melts while ensuring precise temperature control and uniform alloy composition. It is widely used in die casting, alloy preparation, degassing before casting, and other aluminum processing applications.

2. Can this furnace be used for both melting and holding aluminum?

Yes, this is a melting and holding furnace that can efficiently melt aluminum and maintain its temperature for prolonged periods to ensure high-quality casting.

3. What energy sources does the furnace support?

The furnace supports two energy sources:

- Electricity

- Natural gas

You can choose the option that best fits your facility's infrastructure and energy efficiency goals.

4. How does the furnace minimize aluminum burning loss?

The aluminum in the crucible is heated evenly through heat conduction, avoiding localized high temperatures. This reduces oxidation, high-temperature volatilization, and burning loss, keeping aluminum loss to less than 1.2%.

5. Is it possible to use this furnace for different types of alloys?

Yes, the crucible is replaceable, allowing you to process various aluminum alloys without contamination. This makes it highly versatile for multiple alloy production needs.

6. What safety features are included in the furnace?

The furnace is equipped with several safety mechanisms, including:

- Aluminum liquid over-temperature alarm

- Furnace cavity over-temperature alarm

- Crucible leakage alarm

- Water leakage system at the bottom to safely channel molten aluminum in case of a crucible failure

7. How accurate is the temperature control system?

The furnace uses a series-loop temperature control system, ensuring precise heating and preventing overheating of both the furnace and molten aluminum.

8. What is the thermocouple protection material, and why is it important?

The thermocouple protection tube is made of silicon nitride, which offers excellent thermal conductivity, corrosion resistance, and durability. It ensures accurate temperature readings and lasts for more than two years, even under continuous use in molten aluminum.

9. Is this furnace suitable for die-casting applications?

Yes, the aluminum holding furnace for die casting is specifically designed to provide high-quality molten aluminum with precise temperature control, making it ideal for die-casting operations.

10. How does the water leak system improve safety?

The water leak system at the bottom of the furnace allows molten aluminum to flow out safely in case of a crucible failure. This reduces the risk of damage to the furnace and enhances operational safety.

11. What sizes or models are available?

The furnace is available in several models, each with different capacities and melting rates. Please refer to the product table for detailed specifications or consult our team to find the right model for your needs.

12. How can I purchase this aluminum melting and holding furnace?

You can contact us directly via email or phone for inquiries, product details, and quotations. We also offer customized solutions to meet your specific production requirements.

Whatsapp/Mob/Wechat: 008613394110095

Email: [email protected]

Website: www.aluextrusionpress.com