Gas Molten Aluminum Alloy Holding Furnace

The aluminum melting and holding furnace can improve the mechanical properties of the alloy, enhance the corrosion resistance, improve the processing performance, and improve the performance stability.

Photos of

Detailed introduction

At Jiuying, we are committed to providing innovative and efficient industrial solutions. Our aluminium holding furnace is designed to ensure stable heat preservation and optimal performance for aluminum alloy melting and casting processes. Below, we detail its working principle, features, and benefits, demonstrating why this equipment is a must-have for your production line.

Working Principle and Temperature Control

The primary purpose of the aluminium holding furnace is to maintain the liquid aluminum alloy's temperature. With a recommended operating range of 660–720℃, the furnace ensures consistency and reliability in die-casting, centrifugal casting, gravity casting, and precision casting operations. The maximum temperature capability of under 1000℃ provides flexibility for diverse applications.

This furnace's heating source is flat flame type gas burning machine (with a flue gas recycling preheating device), Flat flame gas machine mounted on the rooftop, above liquid aluminum, radiation area is large, and the heating effects better (the temperature of the molten liquid into the furnace must not lower than the operating temperature).

Applications and Range of Work

Our melting and holding furnace is an indispensable addition to any casting operation. Designed specifically for die-casting machines, it seamlessly integrates into manufacturing workflows, supporting various processes:

- Die-Casting: For precision parts with complex geometries.

- Centrifugal Casting: To produce hollow cylindrical components.

- Gravity Casting: For durable and heavy-duty aluminum parts.

- Precision Casting: For high-quality, intricate molds.

The aluminum holding furnace ensures the molten aluminum's temperature is consistent, avoiding costly disruptions and defects in casting.

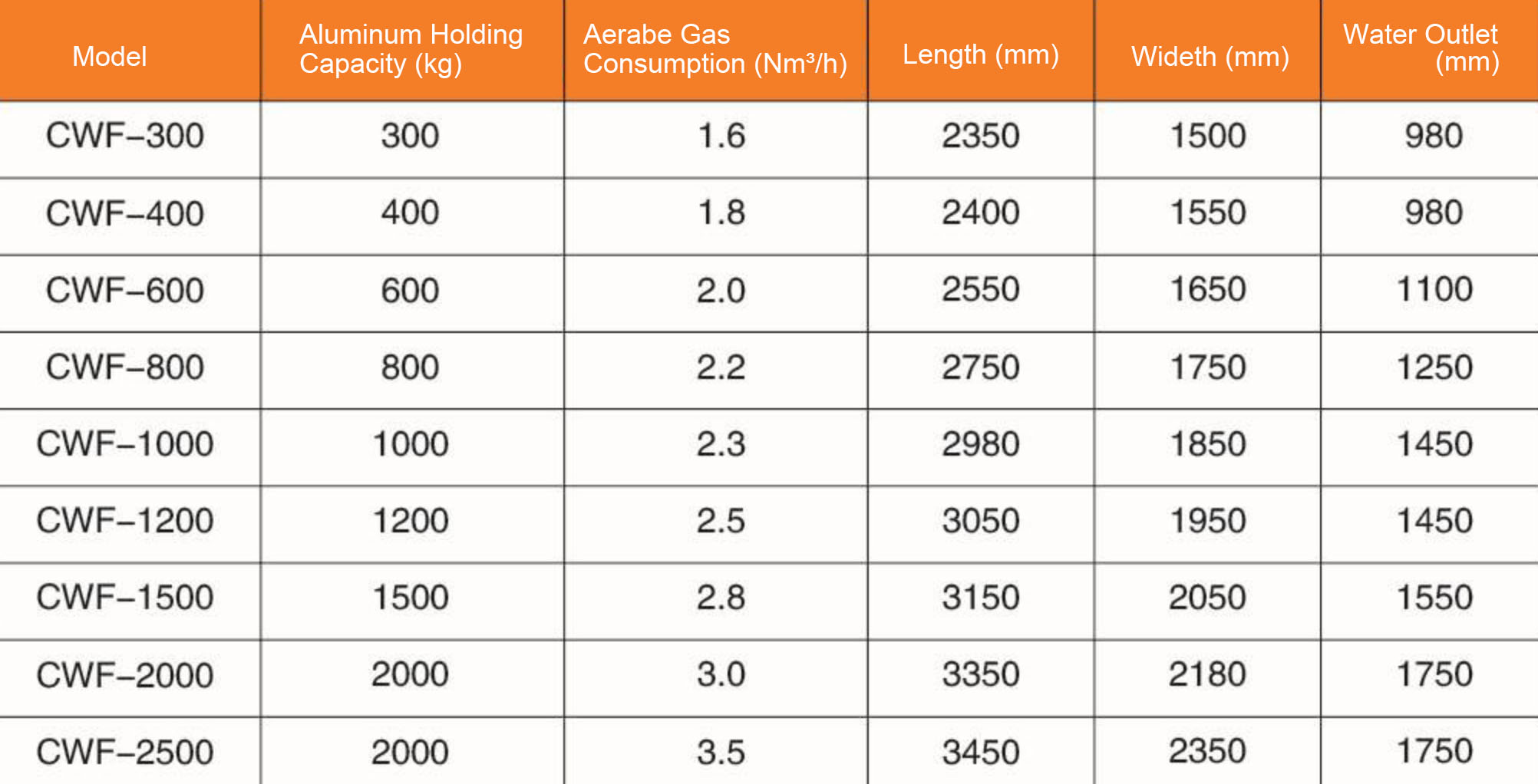

Main Technical Parameters

Note: The above are standard specifications, and can also be designed and produced according to user requirements.

Why Choose Jiuying's Aluminium Holding Furnace?

Enhanced Efficiency

The large radiation area from the flat flame gas burner ensures better heating effects, reducing energy consumption while maintaining performance.Customizable Integration

Our holding furnace for casting is compatible with various casting processes, making it versatile for different industries.Durability and Safety

Built with high-quality materials, the furnace withstands rigorous use and high temperatures. The preheating device and flue gas recycling enhance safety and sustainability.Optimized Design

Designed for reliability, the aluminum melting and holding furnace minimizes thermal losses and maintains uniform heat distribution, improving the quality of your output.

Increase Productivity and Save Costs

By maintaining consistent temperatures and integrating seamlessly with your existing equipment, our aluminum melting and holding furnace ensures smooth operations, minimal downtime, and reduced waste.

At Jiuying, we prioritize quality, innovation, and your success. Choose our holding furnace die casting solution to elevate your production efficiency and meet your customers’ demands with precision.

For inquiries, please contact us via:

Email: [email protected]

Phone: +0086 13394110095