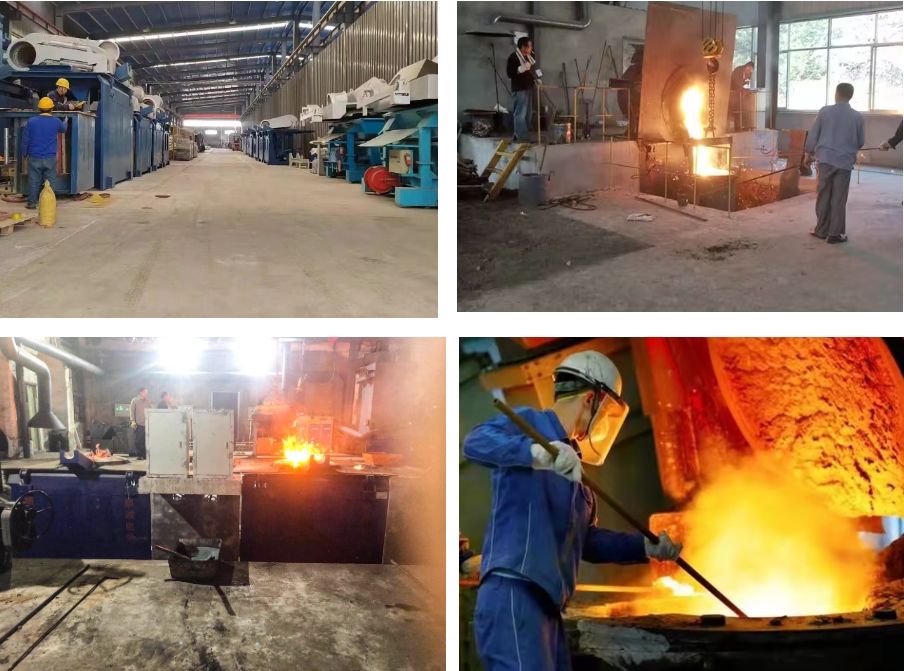

Photos of

Detailed introduction

Jiuying (JY) once again leads the industry and proudly launches a new IGBT precision casting furnace, providing unparalleled efficiency and quality assurance for your production. Whether it is speed, energy consumption, or reliability, our products are industry leaders and will bring revolutionary changes to your production.

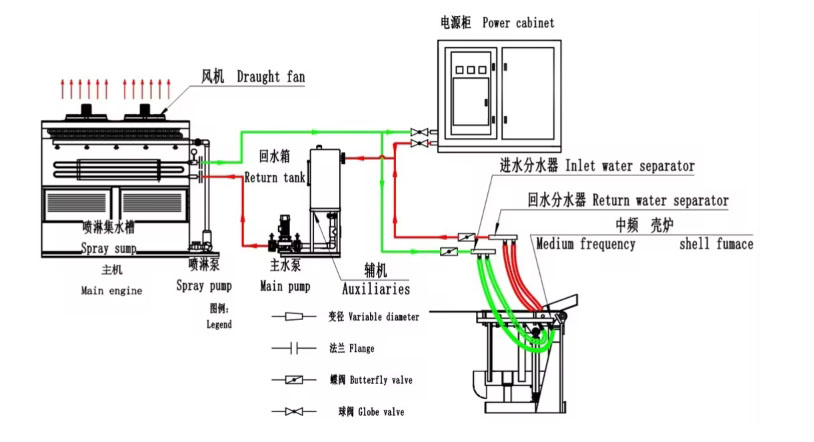

Sketch Map

Working principle

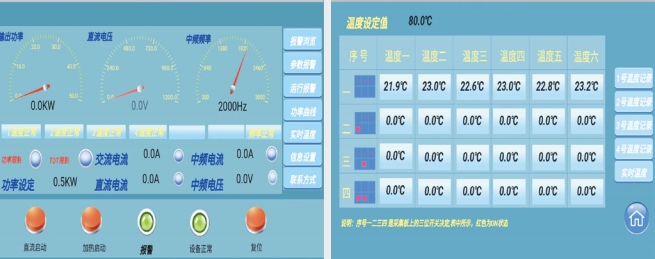

Our special furnace for IGBT precision casting uses advanced IGBT medium frequency power supply and special furnace type. It combines the needs of precision casting technology and many years of R&D experience to provide you with a perfect solution. Through fully digital system control, we ensure the precise adjustment of power parameters, make the equipment work stably, reduce the equipment failure rate, and provide reliable guarantee for your production.

Performance characteristics

High efficiency and energy saving: fast melting speed, low energy consumption, high thermal efficiency, and low loss of metal elements, saving you costs and reducing pollution.

Stable and reliable: fully digital system control, remote control and maintenance are more convenient, the equipment failure rate is lower, and the system operation is more stable, providing continuous stability for your production.

Convenient operation: The equipment starts smoothly, has reliable protection, and is more convenient to operate. It is suitable for automated production and saves you labor costs.

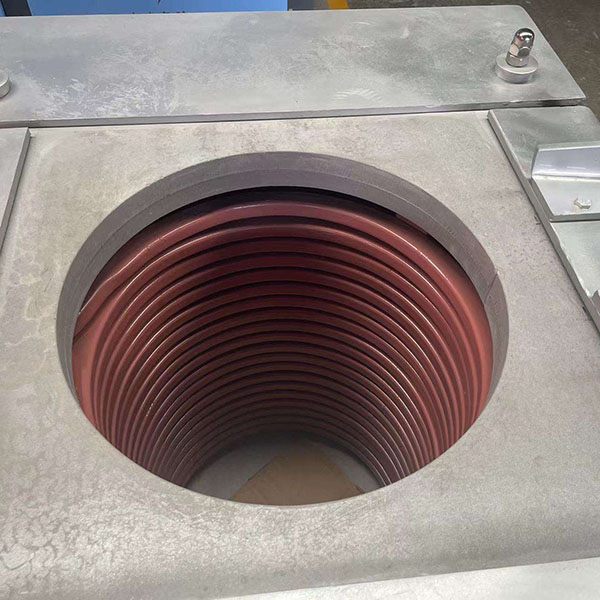

Product details

Integrated design: Both the power supply and the furnace body can be closed as an integrated machine, without the need for an external water cooling system, which reduces heat loss and overall hidden dangers, making long-term use more secure.

Customized structure: The furnace structure is customized according to the special needs of the customer's on-site use. Manual pouring is convenient and fast, reducing the complexity of the operation process and improving production efficiency.

Intelligent control: Fully digital intelligent system control realizes human-machine separation operation, which facilitates enterprise management and equipment maintenance, reduces operating costs and improves production efficiency.

Product advantages

Our IGBT precision casting furnace not only leads similar products in terms of energy efficiency, but also has the following advantages:

Energy saving and environmental protection: It saves more than 30% energy than traditional thyristor equipment, saving energy costs for your production and reducing the impact on the environment.

Efficient production: The fastest melting speed is only 18 minutes per furnace, which improves production efficiency, shortens the production cycle, and wins more business opportunities for you.

Convenient operation: Fully digital intelligent system, separated human and machine operation, facilitates enterprise management and equipment maintenance, reduces operating costs and improves production efficiency.

Why choose our products

In the field of modern industry, precision casting is a vital process that requires efficient, stable and reliable equipment to achieve. In order to meet this demand, Jiuying (JY) is honored to launch a new IGBT precision casting furnace. This furnace combines the most advanced technology and technology to provide a comprehensive solution for your production.

Innovative technology, excellent performance

Our IGBT precision casting special furnace uses the most advanced IGBT medium frequency power supply and special furnace type, combined with many years of R&D experience to ensure efficient energy consumption and stable performance. Not only that, our equipment also has an intelligent control system, which can realize remote control, fault diagnosis and data monitoring, providing you with unprecedented convenience.

Energy saving and environmental protection, promoting sustainable development

As society attaches great importance to environmental protection and sustainable development, our stoves are committed to energy saving and emission reduction. Adopting international standard design and equipped with complete protection functions, it can not only save energy but also reduce the impact on the environment. Our furnace structure complies with national standards, with a power factor as high as 0.98. The low harmonic design is to protect the stable operation of the power grid.

Customized services to meet individual needs

Each customer's production needs are unique, so we provide customized services and personalized designs based on the customer's actual situation. Both the furnace structure and the control system can be adjusted according to customer needs to ensure a perfect match between the equipment and the production line.

Stable and reliable, ensuring smooth production

Stability and reliability are one of the core competitiveness of our products. We select components from well-known brands to ensure the startup performance and operational stability of the equipment. Whether on a busy production line or in a harsh work environment, our furnaces perform consistently to protect your production.

Open the future and move forward hand in hand with Jiu Ying

The special furnace for IGBT precision casting is Jiuying's innovative attempt in the industry. We will always adhere to the concept of "customer-centered and continuous innovation" to provide customers with better products and more satisfactory services. Choose Jiuying, choose the future, let us work together to create a better tomorrow!

Differences from similar machines

Compared with similar machines, our IGBT precision casting furnace has higher energy efficiency, faster melting speed, more stable performance and more convenient operation, bringing greater competitive advantages to your production.

Application scenarios

Our products are widely used in various precision casting industries, including automobile manufacturing, aerospace, mold manufacturing and other fields, providing customers with first-class production solutions.

Industry application cases

Automotive Manufacturing:

In the manufacturing of automotive engine parts, our furnaces ensure precision and quality of castings. For example, in the production of automobile engine blocks, our furnaces can precisely control the temperature and fluidity of the metal, thereby ensuring perfect molding of the castings and improving the performance and reliability of the automobile engine.

Aerospace industry:

In the aerospace industry, the requirements for precision and high temperature resistance of components are extremely high. Our furnaces can be used to cast key components such as aircraft engine blades and turbines, ensuring the safety and performance of aircraft.

Electronic equipment manufacturing industry:

In the electronic equipment manufacturing industry, our furnaces can be used to cast key components such as radiators and casings to ensure the stability and durability of electronic equipment. For example, in the manufacture of high-performance computers, our furnaces can ensure good heat dissipation by the radiator, thereby improving the performance and stability of the computer.

Successful case sharing

Auto parts manufacturer A:

Company A adopted our special IGBT precision casting furnace, which significantly improved the production efficiency and quality of automobile engine parts. Through precise temperature control and flow adjustment, they successfully reduced casting defect rates and improved product consistency and reliability.

Aerospace parts manufacturing company B:

Company B used our furnace when producing aero-engine blades and turbines, and achieved remarkable results. They have successfully improved the precision and high-temperature resistance of parts, met the strict requirements for parts quality in the aerospace industry, and won the trust and recognition of customers.

Inquiry

If you are interested in our products or have any questions, please feel free to contact us, we will be happy to provide you with the best quality services and solutions. Look forward to working with you!

Frequently Asked Questions (FAQs)

1. What types of casting processes is this IGBT precision casting furnace suitable for?

Our IGBT precision casting furnace is suitable for various types of casting processes, including but not limited to die casting, sand casting, and lost wax casting. Whether casting automotive components, aerospace engine blades, or electronic device casings, our furnace can meet your requirements.

2. How much cost and time are involved in the maintenance and upkeep of this equipment?

Our IGBT precision casting furnace is designed for low-cost maintenance and upkeep. Typically, regular cleaning and lubrication are necessary to ensure the stable operation of the equipment. We provide detailed maintenance manuals and training to help you properly maintain and care for the equipment.

3. Is training provided to ensure the correct use of the equipment?

Yes, we provide comprehensive training courses covering equipment operation, maintenance, and safety procedures. Our professional technical team will provide detailed training for you and your staff to ensure correct operation and maintenance of the equipment.

4. What is the production capacity of this equipment?

Our IGBT precision casting furnace has efficient production capacity to meet your production needs. Production capacity depends on various factors, including product size, casting materials, and process requirements. Our sales team will tailor the best solution for you based on your specific requirements.

5. Does this equipment comply with international safety standards?

Yes, our IGBT precision casting furnace complies with international safety standards and has been certified accordingly. We strictly adhere to safety regulations and standards to ensure the safety and stability of the equipment.

6. Is after-sales service and technical support provided?

Yes, we provide comprehensive after-sales service and technical support. Our professional technical team is available to promptly assist you with any issues you may encounter. We also offer regular equipment inspection and maintenance services to ensure the long-term stable operation of the equipment.