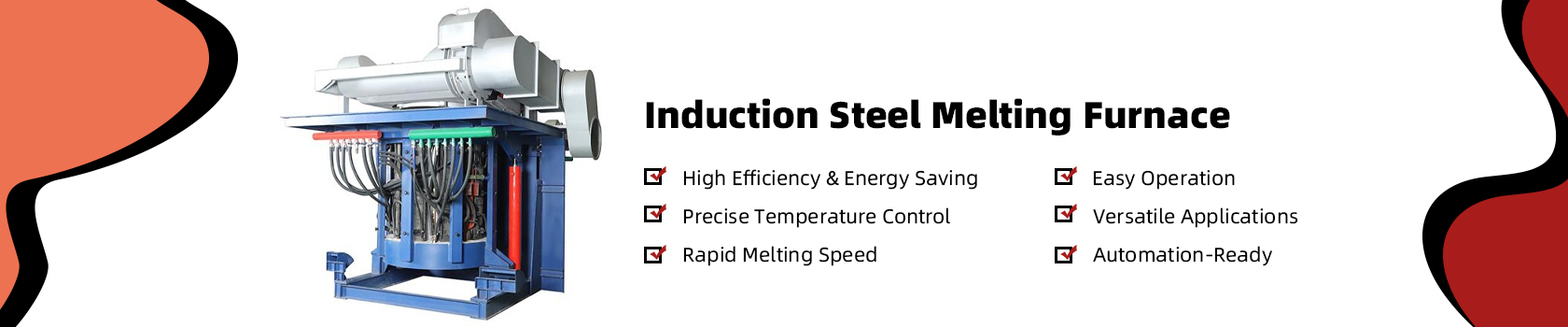

Photos of

Detailed introduction

Medium frequency induction heating furnaces are cutting-edge tools in the realm of industrial heating processes, revolutionizing how metals are heated and treated for various applications. Powered by advanced technology, these furnaces offer precise control, high efficiency, and versatility in heating a wide range of metal workpieces.

How it Works

Medium frequency induction heating furnaces utilize electromagnetic induction to generate heat within the metal workpiece. A high-frequency alternating current is passed through an induction coil, creating a rapidly changing magnetic field. This field induces electrical currents, known as eddy currents, within the workpiece, leading to rapid and uniform heating.

Key Features

- Precise Heating: These furnaces offer precise and localized heating, allowing for controlled heating profiles tailored to specific metallurgical requirements.

- High Efficiency: With minimal heat loss and rapid heating rates, medium frequency induction furnaces are highly energy-efficient, reducing operational costs and improving productivity.

- Versatility: Suitable for a wide range of applications, including forging, melting, brazing, and heat treatment, these furnaces offer versatility across various industries such as automotive, aerospace, and manufacturing.

Uniform Heating: The induction heating process ensures uniform heating throughout the workpiece, minimizing temperature variation and achieving consistent metallurgical properties.

Applications

Medium frequency induction heating furnaces are versatile tools widely used across various industries for a multitude of applications. Their precise heating capabilities, efficiency, and uniformity make them indispensable for processes where controlled heat treatment is essential. Here are some common applications:

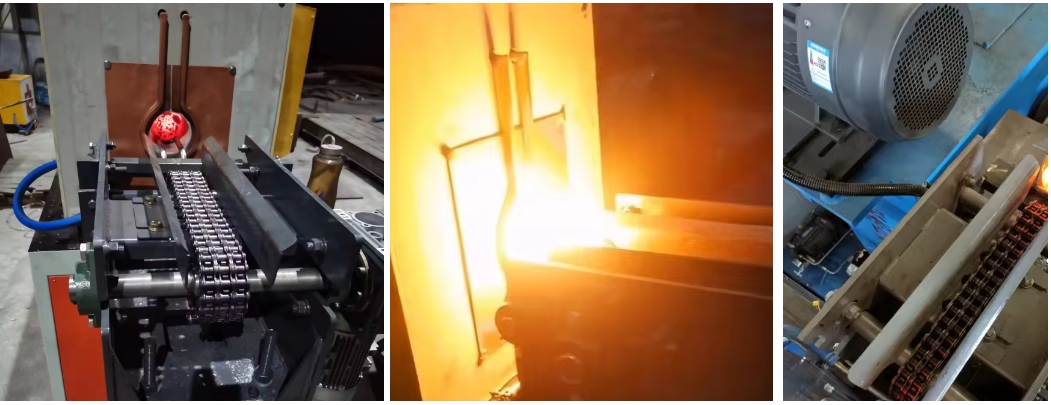

Forging and Forming

Medium frequency induction heating furnaces are used in forging and forming processes to heat metal billets or ingots to the required temperature for shaping and molding into desired shapes. Applications include forging automotive components, gears, shafts, and hand tools.

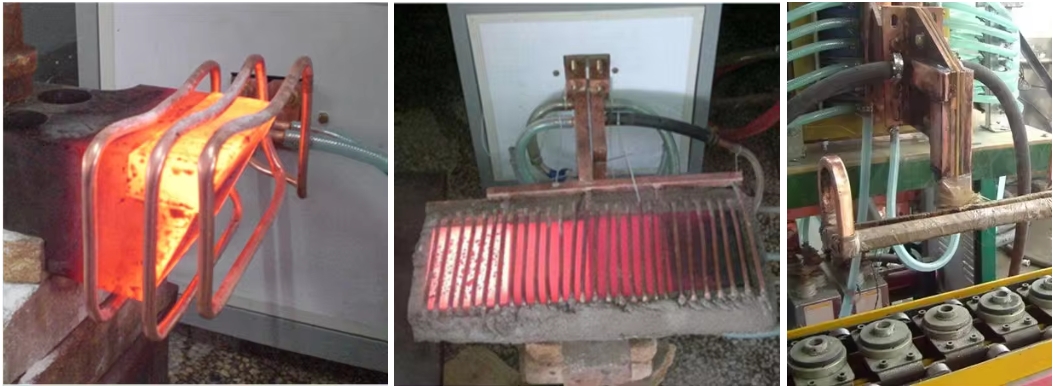

Melting and Casting

These furnaces are employed for melting and casting metals, both ferrous and non-ferrous, in foundries and metallurgical plants. They are utilized in industries such as automotive, aerospace, and metalworking for casting components like engine blocks, cylinder heads, turbine blades, and intricate parts with precision.

Heat Treatment

Heat treatment processes such as annealing, hardening, tempering, and quenching are crucial for improving the mechanical properties of metals. Medium frequency induction heating furnaces provide precise control over heating rates and temperatures, ensuring uniform heat distribution and consistent metallurgical outcomes.

Brazing and Soldering

These furnaces are used for brazing and soldering applications where joining of metal components is required. The controlled heating provided by medium frequency induction heating ensures strong and durable bonds between the materials, making them suitable for industries such as electronics, aerospace, and automotive manufacturing.

Surface Hardening

Surface hardening processes like induction hardening and case hardening are employed to improve the wear resistance and durability of metal surfaces. Medium frequency induction heating furnaces are used to selectively heat the surface of components, followed by quenching, resulting in hardened surface layers while maintaining the core properties of the material.

Tube and Pipe Welding

Medium frequency induction heating is utilized for preheating and post-weld heat treatment in tube and pipe welding processes. It helps reduce welding defects, improve weld quality, and increase productivity in industries such as oil and gas, construction, and pipeline manufacturing.

Annealing and Tempering

Annealing and tempering processes are essential for relieving internal stresses, refining grain structures, and achieving desired material properties. Medium frequency induction heating furnaces provide precise control over heating and cooling rates, making them ideal for annealing and tempering applications in the steel, aerospace, and automotive industries.

Induction Brazing and Soldering

Medium frequency induction heating furnaces are utilized in brazing and soldering applications for joining metal components with precision and efficiency. Industries such as electronics, aerospace, and automotive manufacturing rely on induction brazing and soldering for producing high-quality assemblies with minimal heat distortion.

Why Choose Medium Frequency Induction Heating Furnaces

- Efficiency: Reduced heating times and minimal energy wastage result in cost savings and increased productivity.

- Precision: Precise control over heating parameters ensures consistent results and high-quality metallurgical outcomes.

- Versatility: Capable of handling a wide range of metal types, shapes, and sizes, making them suitable for diverse industrial applications.

- Safety: Induction heating is a clean and safe process, minimizing workplace hazards associated with traditional heating methods such as flames or electric resistance.

Device Features

- Fast Heating: Rapid heating with minimal oxidation and decarburization, low energy consumption, and high thermal efficiency.

- Digital System Control: Precise adjustment of power parameters, accurate temperature control, uniform heating of workpieces, and reduced component damage, ensuring stable system operation.

- Simple Production Operation: Easy operation, flexible material handling, high degree of automation, capable of online production and remote control.

- Comprehensive Protection Features: Equipped with various protections such as water temperature, water pressure, phase loss, overvoltage, overcurrent, pressure limiting, current limiting, startup overcurrent constant current, and soft start, ensuring smooth startup and reliable protection, as well as reliable speed and stable operation.

- Digital Input for Intelligent Control: Allows precise parameter setting, constant power output, and stable equipment operation.

- Menu-style Program Loading: CNC programming operation, instant adjustment without repeated tuning, saving time and labor, and ensuring reliable heating quality.

- IoT Remote Control: Remote data collection, online diagnosis and maintenance, facilitating customer control, and proactive after-sales service.

- Independent Temperature Control Module: Real-time independent monitoring, advance temperature prediction, timely fault warning, reducing the occurrence of faults.

- One-Key Insulation: Avoids the situation where the entire batch of billets cannot be used due to problems in other processes.

- Online Closed-Loop Temperature Control: No material discharge if the temperature is not reached, avoiding problems such as sticking, burning, and blackening due to unstable voltage.

New Digital IGBT Heating Efficiency: High power factor (above 0.95), saving 10-20% electricity. Adopts new German Infineon module technology to increase coil voltage, reduce line loss, maintain constant power output, improve power factor, and achieve energy saving goals, saving 10-20% electricity compared to traditional parallel equipment.

GTR Series Diathermy Furnace Technical Parameters

| Model | Power Input | Power Output | |||||

| Inlet line Votag(V)3 phases or 6 phases 50Hz | Inlet Current (A) | DC Voltage (V) | DC Current (A) | MF Frequency (KHz) | MF Voltage (v) | MF Power (KW) | |

| GTR-60 | 380 | 100 | 500 | 120 | 1~8 | 750 | 60 |

| GTR-100 | 380 | 160 | 500 | 200 | 1~8 | 750 | 100 |

| GTR-120 | 380 | 200 | 500 | 240 | 1~8 | 750 | 120 |

| GTR-160 | 380 | 260 | 500 | 320 | 1~8 | 750 | 160 |

| GTR-200 | 380 | 330 | 500 | 400 | 1~8 | 750 | 200 |

| GTR-250 | 380 | 410 | 500 | 500 | 1~8 | 750 | 250 |

| GTR-300 | 380 | 490 | 500 | 600 | 0.4~8 | 750 | 300 |

| GTR-400 | 380 | 650 | 500 | 800 | 0.2~6 | 750 | 400 |

| GTR-500 | 380 | 820 | 500 | 1000 | 0.2~6 | 750 | 500 |

| GTR-750 | 380 | 1200 | 500 | 1500 | 0.2~6 | 750 | 750 |

| GTR-750 | 660 | 680 | 890 | 850 | 0.2~6 | 1300 | 750 |

| GTR-1000 | 380 | 1650 | 500 | 2000 | 0.2~1 | 750 | 1000 |

| GTR-1000 | 660 | 920 | 890 | 1150 | 0.2~1 | 1300 | 1000 |

| GTR-1500 | 380 | 2500 | 500 | 3000 | 0.2~1 | 750 | 1500 |

| GTR-1500 | 660 | 1400 | 890 | 1700 | 0.2~1 | 1300 | 1500 |

| GTR-2000 | 580 | 2100 | 780 | 2600 | 0.2~0.5 | 1170 | 2000 |

| GTR-2000 | 660 | 1850 | 880 | 2300 | 0.2~0.5 | 1300 | 2000 |

FAQs - Medium Frequency Induction Heating Furnace

What types of casting processes is this IGBT precision casting furnace suitable for?

Our IGBT precision casting furnace is suitable for various types of casting processes, including but not limited to die casting, sand casting, and lost wax casting. Whether casting automotive components, aerospace engine blades, or electronic device casings, our furnace can meet your requirements.

How much cost and time are involved in the maintenance and upkeep of this equipment?

Our IGBT precision casting furnace is designed for low-cost maintenance and upkeep. Typically, regular cleaning and lubrication are necessary to ensure the stable operation of the equipment. We provide detailed maintenance manuals and training to help you properly maintain and care for the equipment.

Is training provided to ensure the correct use of the equipment?

Yes, we provide comprehensive training courses covering equipment operation, maintenance, and safety procedures. Our professional technical team will provide detailed training for you and your staff to ensure correct operation and maintenance of the equipment.

What is the production capacity of this equipment?

Our IGBT precision casting furnace has efficient production capacity to meet your production needs. Production capacity depends on various factors, including product size, casting materials, and process requirements. Our sales team will tailor the best solution for you based on your specific requirements.

Does this equipment comply with international safety standards?

Yes, our IGBT precision casting furnace complies with international safety standards and has been certified accordingly. We strictly adhere to safety regulations and standards to ensure the safety and stability of the equipment.

Is after-sales service and technical support provided?

Yes, we provide comprehensive after-sales service and technical support. Our professional technical team is available to promptly assist you with any issues you may encounter. We also offer regular equipment inspection and maintenance services to ensure the long-term stable operation of the equipment.