Photos of

Detailed introduction

Aluminum melting furnaces play a crucial role in the manufacturing industry, particularly in metal casting processes where precise temperature control and efficient melting are essential. Among the various types of furnaces available, the Aluminum Shell Melting Furnace stands out for its technical advantages, reliability, and cost-effectiveness.

Standard Configuration of Furnace

Technical Advantages

The Aluminum Shell Melting Furnace, powered by Medium Frequency (MF) technology, offers several technical advantages:

- Low Equipment Cost: One of the key benefits of this furnace is its low equipment cost. The equipment structure is relatively simple, resulting in cost savings without compromising on performance.

- Mature Technology: With over a decade of continuous improvement, the MF technology used in these furnaces has become highly mature. This ensures reliable operation and effective melting processes.

- Adaptability: These furnaces are well-adapted to various environmental conditions, making them suitable for different industrial settings.

- Simple Maintenance: The furnace design incorporates a simple circuit and low-cost components, making maintenance straightforward and cost-effective.

Power Supply

The power supply unit of the Aluminum Shell Melting Furnace is a critical component that ensures efficient and stable operation. It features a Medium Frequency Power Supply with advanced circuit technology:

- Wide Frequency Scope

- Constant Capacity Control

- Automatic Zero-Pressure Start

- Double Voltage and Currency Closed-Loop Feedback System

Rigorous Protections: Overcurrent, Overvoltage, Undercurrent, Undervoltage, Lack of Water, Default Phase

Product Features

The Aluminum Shell Melting Furnace boasts a range of features that enhance its performance and usability:

- Various Capacities: Available in capacities ranging from 0.1T to 20T, these furnaces offer fast melting speeds, with each pot typically melting within 40-60 minutes.

- Self-Test Function: Real-time supervision is facilitated by a built-in self-test function, ensuring efficient operation.

- Leak Alarm Device: Equipped with a leaking alarm device and PLC control, these furnaces are easy to operate and maintain.

- Standard Control Cabinet: The control cabinet adheres to automobile line standards, simplifying maintenance procedures.

- High-Quality Materials: The waterway utilizes carbon-free hose, while water separators and clips are made of 304 stainless steel, ensuring durability and longevity.

- Continuous Operation: These furnaces are designed to meet the demands of 24-hour continuous work, making them ideal for industrial applications.

- Efficiency and Energy Saving: With high efficiency, low operating costs, and energy-saving features, these furnaces offer a cost-effective solution for metal melting processes.

Enclosed Type Water Cooling System

The cooling system of the Aluminum Shell Melting Furnace is designed for optimal performance and longevity:

- High-Quality Materials: The coil group is made of high-quality T2 depickling copper tube or stainless steel pipe, ensuring long service life.

- Efficient Cooling: The enclosed type water cooling system utilizes a spray system with a collection device, reducing water consumption and ensuring efficient cooling.

- Low Operating Costs: With a professional full-closed low-speed low-power motor, the cooling system operates quietly and consumes minimal power.

- Low Maintenance: Distilled water circulating cooling prevents scaling, resulting in low maintenance costs and extended equipment lifespan.

Space-Saving Design: The water cooling system does not require a water pool, making it suitable for installations where space is limited.

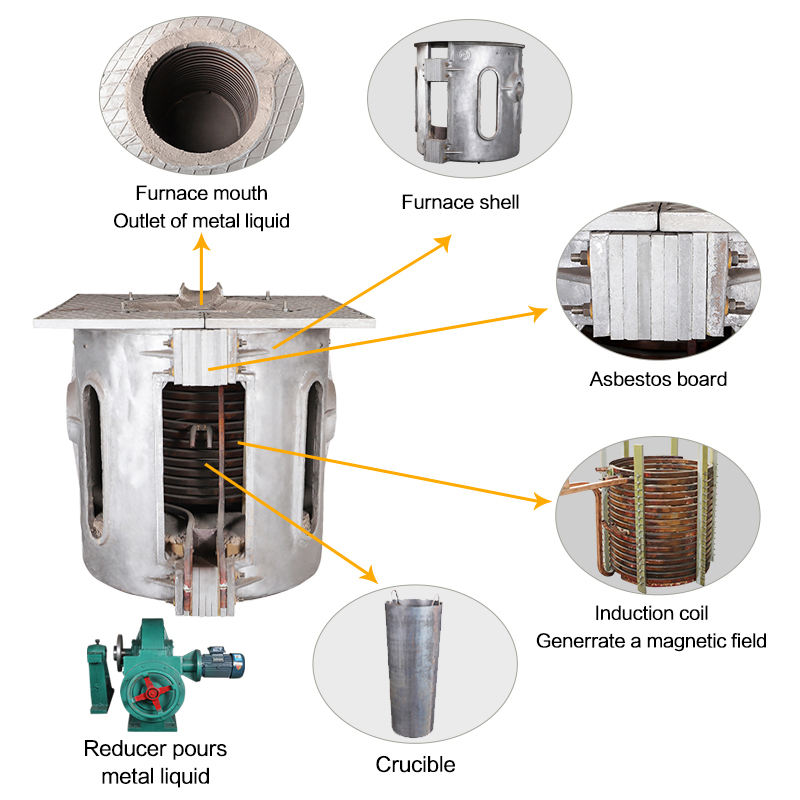

Details Images

Below are some detailed images showcasing the components and features of the Aluminum Shell Melting Furnace:

Furnace Parts: Mechanical components including the furnace pot, water power introduction system, and titling device.

Furnace Ports: Components such as the furnace shell and induction coil.

Furnace Shell: Made of cast aluminum, the furnace shell offers good rigidity, compact structure, and easy maintenance.

Product Paramenters

| Rated Capacity (t) | Rated Power (KW) | Input Power | Outlet Power | ||

| Inlet Voltage(v) | Inlet Current(A) | MF Voltage (V) | Rated Frequency (KHz) | ||

| 0.15 | 100⁓160 | 3N-380 | 160⁓260 | 750 | 1⁓2.5 |

| 0.25 | 160⁓250 | 3N-380 | 260⁓410 | 750 | 1⁓2.5 |

| 0.35 | 200⁓400 | 3N-380 | 320⁓650 | 750 | 1⁓2 |

| 0.5 | 350⁓500 | 3N-380 | 580⁓830 | 750 | 1⁓1.5 |

| 0.75 | 400⁓600 | 3N-380 | 650⁓1000 | 750 | 0.8⁓1 |

| 1 | 600⁓800 | 3N-380 | 1000⁓1330 | 750 | 0.6⁓1 |

| 1 | 600⁓800 | 3N-660 | 670⁓900 | 1200 | 0.6⁓1 |

| 1.5 | 800⁓1200 | 3N-660 | 900⁓1330 | 1200 | 0.5⁓1 |

| 2 | 1000⁓1500 | 3N-660 | 1120⁓1680 | 1200 | 0.5⁓0.8 |

| 3 | 1500⁓2500 | 3N-660 | 1680⁓2800 | 1200 | 0.3⁓0.6 |

| 5 | 2500⁓3500 | 6N-660 | 2800⁓3900 | 1200 | 0.2⁓0.5 |

| 10 | 4000⁓6000 | 6N-1250 | 2400⁓3600 | 2200 | 0.2⁓0.4 |

| 12 | 5000⁓7000 | 6N-1250 | 3000⁓4200 | 2200 | 0.2⁓0.4 |

Aluminum Shell Melting Furnace FAQ

1. What is an Aluminum Shell Melting Furnace?

The Aluminum Shell Melting Furnace is a type of industrial furnace used for melting aluminum and other non-ferrous metals. It features a shell made of cast aluminum, which offers durability, efficient heat transfer, and easy maintenance.

2. What are the technical advantages of this furnace?

The Aluminum Shell Melting Furnace offers several technical advantages, including low equipment cost, mature technology, adaptability to various environments, and simple maintenance. Its Medium Frequency Power Supply ensures efficient and stable operation.

3. What capacities are available for this furnace?

These furnaces are available in various capacities ranging from 0.1T to 20T. Each pot typically has a fast melting speed, with melting times ranging from 40 to 60 minutes.

4. How does the self-test function work?

The self-test function allows for real-time supervision of the furnace operation. It automatically conducts diagnostic tests to ensure all systems are functioning correctly, providing operators with peace of mind and facilitating maintenance.

5. Is the furnace easy to operate?

Yes, the Aluminum Shell Melting Furnace is designed for ease of operation. It features a leak alarm device, PLC control, and a standard control cabinet following automobile line standards, making it user-friendly and efficient.

6. What materials are used in the water cooling system?

The water cooling system utilizes high-quality materials such as T2 depickling copper tube or stainless steel pipe for the coil group. Additionally, the waterway uses carbon-free hose, while water separators and clips are made of 304 stainless steel.

7. Can the furnace operate continuously?

Yes, the Aluminum Shell Melting Furnace is designed to meet the demands of 24-hour continuous work. Its robust construction and efficient cooling system ensure reliable performance even under extended operation.

8. How does the enclosed type water cooling system work?

The enclosed type water cooling system utilizes a spray system with a collection device to reduce water consumption and ensure efficient cooling. It operates quietly and consumes minimal power, contributing to lower operating costs.

9. What are the maintenance requirements for this furnace?

Due to its simple circuit design and low-cost components, the Aluminum Shell Melting Furnace requires minimal maintenance. Routine inspections and cleaning of the cooling system are recommended to ensure optimal performance and longevity.

10. Is technical support available for this furnace?

Yes, technical support and assistance are available for the Aluminum Shell Melting Furnace. Our team of experts can provide guidance on installation, operation, and maintenance to ensure smooth and efficient operation of the furnace.