Photos of

Detailed introduction

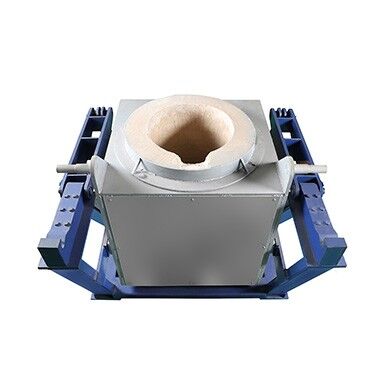

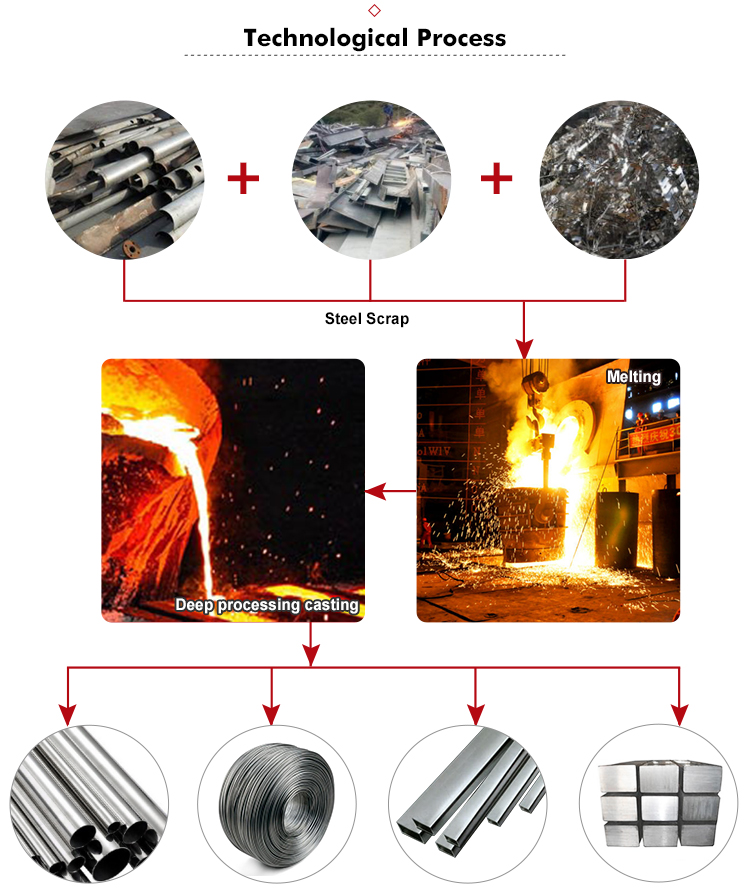

Working Principle of the Stainless Steel Melting Furnace

The stainless steel melting furnace operates on the principle of electromagnetic induction, a process that generates heat within the material itself rather than relying on external heating elements. This method is highly efficient and ensures uniform heating throughout the material.

Here’s how it works:

- Electromagnetic Induction: The furnace uses an alternating current (AC) passing through a coil to create a rapidly changing magnetic field. When a conductive material, such as stainless steel scrap, is placed within this magnetic field, electric currents (eddy currents) are induced within the material.

- Resistive Heating: These eddy currents flow through the material's resistance, generating heat directly within the material. This process is highly efficient because the heat is produced internally, reducing energy losses and ensuring uniform temperature distribution.

- Melting Process: As the material heats up, it eventually reaches its melting point. The hydraulic tilting mechanism allows for precise pouring of the molten metal, enhancing stability and improving production efficiency.

- Power Supply Optimization: The furnace is designed to improve the resonant part of the power supply, ensuring constant power output even when melting weak magnetic materials. This feature is crucial for maintaining the quality and consistency of the melted material.

The stainless steel melting furnace is equipped with advanced control systems that monitor and adjust various parameters in real-time, such as water temperature, water pressure, and electrical conditions. This ensures optimal performance, safety, and longevity of the equipment.

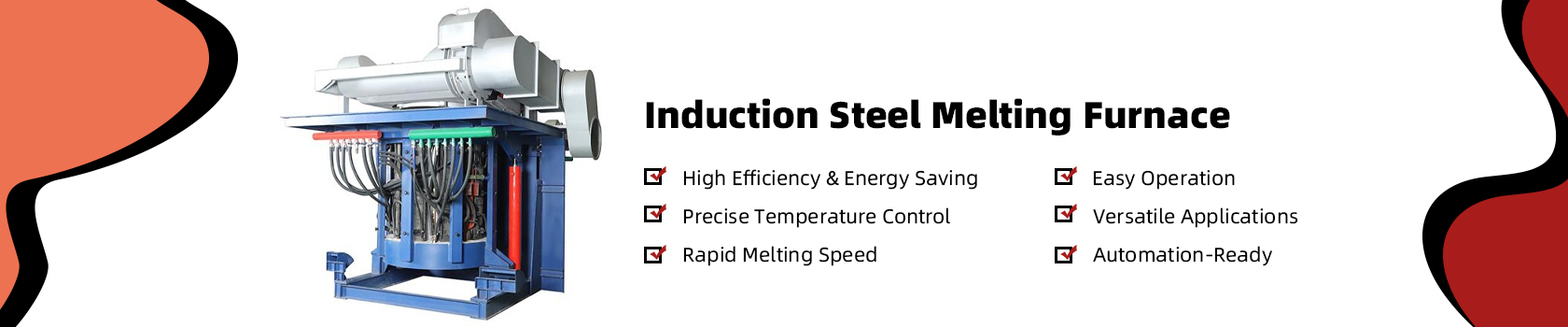

Product Features

- Melting Control System: Customizable control system for accurate melting process management and alloy composition display.

- Self-Test Function: Real-time detection of water temperature, water pressure, over-current, over-voltage, and phase fault information.

- Modular Electrical Cabinet: Easy maintenance with fewer broken parts, suitable for harsh conditions such as dirty, high-temperature, and corrosive environments.

- Constant Power Output: Adjustable power for heating and heat preservation, enhancing product quality and simplifying worker operations.

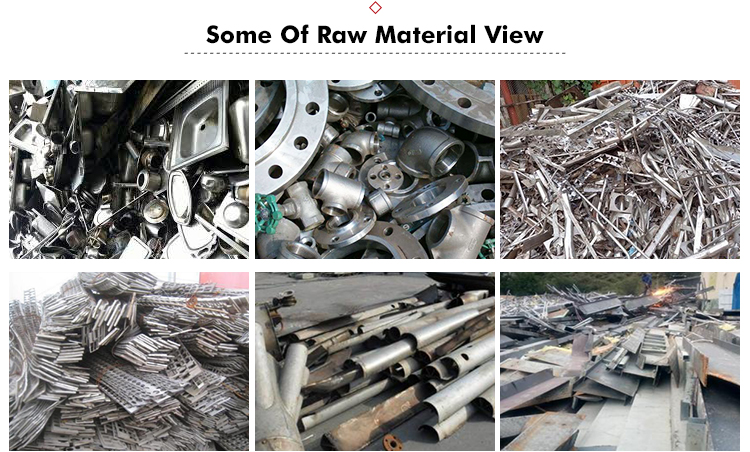

Applications of the Stainless Steel Melting Furnace

The versatility of the stainless steel melting furnace makes it suitable for various industrial applications. Here are some common uses:

- Metallurgical Industry: Ideal for smelting, refining, and heat treatment of metals, including steel, aluminum, copper, and alloys.

- Heat Treatment: Used in processes like annealing, tempering, quenching, and solution treatment to modify metal properties through specific heating and cooling cycles.

- Foundries: Utilized for melting and casting metals, with stainless steel often used as a crucible material due to its high melting point and resistance to chemical reactions.

Why Choose Our Stainless Steel Melting Furnace?

Choosing our stainless steel melting furnace brings numerous advantages to your industrial processes:

- Efficiency: Fast melting speeds (30-100 minutes per pot) and precise control systems improve overall productivity.

- Reliability: Robust construction and real-time monitoring ensure consistent performance and early fault detection.

- Easy Installation: Simple connection to electricity and water, reducing setup time and costs.

- Customizable: Tailored solutions to meet specific customer requirements, including advanced control systems for precise alloy composition management.

Specification:

| Specification and Technical Parameter | |||||

| Model | Power | Input Voltage | MF voltage | Associated Transformer | MF Frequency |

| 0.1T | 100kw | 3×380v | 750v | 125 | 2000Hz |

| 0.25T | 200kw | 3×380v | 750v | 250 | 2000Hz |

| 0.5T | 400kw | 3×380v | 1500v | 500 | 1500Hz |

| 1T | 850kw | 3×660v | 2400v | 900 | 1000Hz |

| 1.5T | 1000kw | 3×660v | 2500v | 1250 | 1000Hz |

| 2T | 1500kw | 3×660v | 2500v | 1600 | 800Hz |

| 5T | 3000KW | 6×950v | 3400V | 3300 | 800Hz |

| 10T | 6000kw | 6×1250v | 3700V | 7200 | 500Hz |

| 15T | 10000KW | 6×1250v | 4000V | 12500 | 300Hz |

Contact Us

If you are interested in our stainless steel melting furnace or have any questions, please do not hesitate to contact us. Our team of experts is ready to assist you with all your needs and provide detailed information about our products and services.

For more information or to request a quote, please fill out our contact form.

Frequently Asked Questions (FAQ)

- 1. What materials can be melted in the stainless steel melting furnace?

- Our stainless steel melting furnace is capable of melting various materials, including stainless steel scrap, steel scrap, aluminum, copper, and various alloys.

- 2. How long does it take to melt a batch of material?

- The melting speed is highly efficient, ranging from 30 to 100 minutes per batch, depending on the material and the furnace model.

- 3. What safety features are included in the stainless steel melting furnace?

- The furnace includes several safety features, such as real-time detection of water temperature, water pressure, over-current, over-voltage, and phase fault information, ensuring safe and reliable operation.

- 4. Is the stainless steel melting furnace suitable for harsh working environments?

- Yes, the furnace is designed to operate in harsh conditions, including dirty, high-temperature, and corrosive environments, thanks to its robust construction and modular electrical cabinet.

- 5. Can the stainless steel melting furnace be customized to meet specific requirements?

- Absolutely. We offer customizable control systems and other features to ensure the furnace meets your specific industrial needs.

- 6. What kind of maintenance does the stainless steel melting furnace require?

- The modular design of the electrical cabinet makes maintenance straightforward and minimizes downtime. Regular checks and maintenance of water and electrical systems will ensure optimal performance.

- 7. How do I get a quote or more information about the stainless steel melting furnace?

- You can contact Jiuying via email at [email protected] or call/WhatsApp/WeChat at +008613394110095. Alternatively, visit our website at www.aluextrusionpress.com for more information or to request a quote.

- 8. What is the power range of the stainless steel melting furnace?

- Our stainless steel melting furnace offers a wide power range to meet different melting requirements, ensuring constant power output for efficient melting.

- 9. How is the stainless steel melting furnace installed?

- The installation process is simple and straightforward. Just connect the furnace to electricity and water, and it’s ready to use.

- 10. Does the stainless steel melting furnace support automated operation?

- Yes, our furnaces come with advanced control systems that support automated operation, enhancing efficiency and reducing the need for manual intervention.

- 11. What industries commonly use the stainless steel melting furnace?

- The furnace is widely used in the metallurgical industry, foundries, and for various heat treatment processes due to its efficiency and versatility.

- 12. Can the furnace handle continuous operation?

- Yes, the stainless steel melting furnace is designed for continuous operation, providing reliable performance over extended periods.

- 13. What are the dimensions and capacity options for the stainless steel melting furnace?

- We offer various models with capacities ranging from 0.5T to 5T, allowing you to choose the best fit for your production needs.

- 14. How does the furnace ensure uniform heating?

- The furnace uses electromagnetic induction to generate heat uniformly within the material, ensuring consistent melting and high-quality output.

- 15. What is the lead time for delivery of a stainless steel melting furnace?

- The lead time varies based on the specific model and customization requirements. Please contact Jiuying for detailed information on delivery times.

- 16. How can I ensure the longevity of the stainless steel melting furnace?

- Regular maintenance and monitoring of the furnace’s water and electrical systems will ensure its longevity and optimal performance.

- 17. Are there any after-sales services provided?

- Yes, Jiuying provides comprehensive after-sales services, including technical support, maintenance, and spare parts supply to ensure your furnace operates smoothly.

- 18. What is the warranty period for the stainless steel melting furnace?

- Our furnaces come with a standard warranty period. For detailed warranty information, please contact Jiuying directly.

- 19. Can I visit the factory to see the stainless steel melting furnace in operation?

- Yes, we welcome potential customers to visit our factory in Dalian City, China. Please contact us to arrange a visit.

- 20. How do I place an order for the stainless steel melting furnace?

- To place an order, please contact Jiuying via email at [email protected] or call/WhatsApp/WeChat at +008613394110095. Our team will guide you through the ordering process and provide any assistance you need.