Photos of

Detailed introduction

Oil Fired Aluminium Melting Furnace: Efficient and Reliable for Your Factory

At Jiuying, we are committed to serving the factory buyer with the best and efficient energy solution for melting aluminum. The oil-fired aluminum melting furnace is designed for perfect melting of scrap aluminum in order to produce high-purity ingot or to support various casting operations. Allow me to take you through everything you may want to know about this furnace-from its working principle, its advantages, its specifications to making a choice for the needs of your factory.

Working Principle

An aluminum-melting furnace that is fired by oil depends on light diesel or oil as the key type of fuel. This furnace operates on the basic principle of having a specially linked burner that combats the fuel of oil to give a range of high temperature. A series operation with accuracy in the operating control of temperature is given in furnaces to help in providing the aluminum at perfect liquid during casting.

The maximum heating temperature possible for aluminum is 950°C, and it ensures that melting can take place with the highest possible speed and efficiency. With the furnace containing a heavy insulation system, the stability in temperature inside the melting can be maintained accordingly. It is suitable for large-scale production, as this furnace works round the clock with at least minimum stoppage.

Product Features and Performance

Following are the advantages of our oil-fired aluminum melting furnace:

High Efficiency: The furnace performs the melting of aluminum very fast with the least consumption of energy, hence optimizing your time and production cost.

Energy Economy: Our oil-fired models save up to 30% on energy compared with electric furnaces, substantially reducing your operating costs.

Low Aluminum Loss: The furnace is designed to hold loss at less than 3%, hence assuring more material recovered and at much lesser cost.

Advanced Control Systems: The furnace is equipped with automatic temperature control, ensuring stable melting and easy operation. The dual-temperature control system regulates the temperature of melting and holding to maintain consistent quality in the metal.

Durable Design: The furnaces are made from high-quality materials, including SIC crucibles, coupled with a high-quality burner that enables the furnaces to serve without much wear and tear resulting from daily industrial use.

Furnace Models and Specifications

Our oil-fired aluminum melting furnace is provided in several models of full range capacity and specification that meet your needs. Following are the details for our standard models:

| Model | Melting Capacity | Crucible Capacity | Burner Power | Dimensions (LWH) |

|---|---|---|---|---|

| JY-350 | 150 kg/h | 350 kg | 20 x 10⁴ Kcal/h | 1750 x 2050 x 2050 mm |

| JY-500 | 200 kg/h | 500 kg | 30 x 10⁴ Kcal/h | 2000 x 2280 x 2150 mm |

| JY-600 | 300 kg/h | 600 kg | 30 x 10⁴ Kcal/h | 2050 x 2280 x 2150 mm |

| JY-800 | 350 kg/h | 800 kg | 40 x 10⁴ Kcal/h | 2200 x 2400 x 2300 mm |

| JY-1000 | 450 kg/h | 1000 kg | 40 x 10⁴ Kcal/h | 2200 x 2400 x 2500 mm |

These models come with either electrical or hydraulic tilting systems, depending on your preference. The diverse range of capacities ensures that we can meet the specific requirements of any factory, whether you need a smaller furnace for low-volume operations or a high-capacity solution for industrial-scale production.

Why Choose Jiuying?

Jiuying is not only a furnace provider — we are your partner for production efficiency. The following are some of the reasons why our customers like our products:

One-Year Warranty: We guarantee the longevity of our furnaces with a one-year warranty, so you have peace of mind with each purchase.

100% Customization: Be it customized colors, labels or technical modifications, we offer fully customizable solutions for your factory.

Multilingual Support: Our technical support representatives are fluent in Russian, Spanish and English so that we can reach you smoothly and support you no matter where you are.

Short Response Time: We know the pressure of the factory. That’s why we guarantee an hour response to all inquiries so you get the information and assistance that you require in a timely manner.

Price-Rich Solutions: Not only are our oil furnaces more energy efficient than electric furnaces, they also prevent aluminum loss to help save you money in the long run.

Our aluminium melting furnaces are supported by certifications confirming their compliance with global quality, safety and environmental regulations. These certifications are ISO 9001 (quality system), ISO 14001 (environment management), OHSAS 18001 or ISO 45001 (workplace safety and health). These certifications reflect our dedication to providing proven and eco-friendly solutions for industrial melting applications.

Contact Us

Contact: Mr. Liu (manager)

Whatsapp/Mob/Wechat: 008613394110095

Email: [email protected]

Website: www.aluextrusionpress.com

Address: 20# Ganwang Street, Dalian City, China

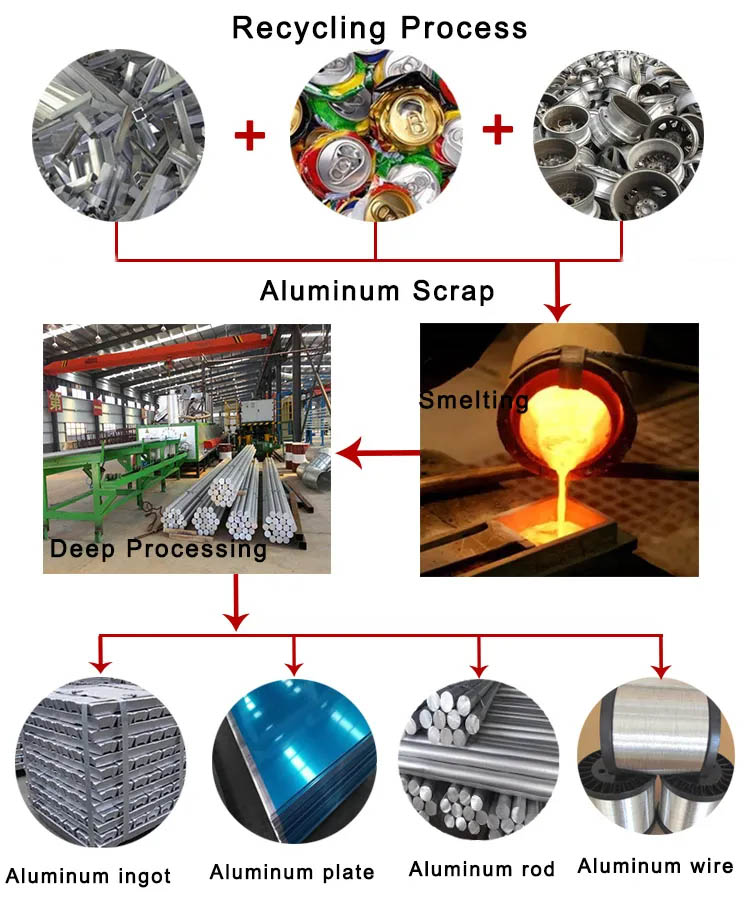

Applications of the Oil Fired Aluminium Melting Furnace

Our oil fired aluminium melting furnace is used across a wide range of industries:

- Aluminum Die-Casting: Ideal for melting aluminum for die-casting applications, ensuring consistent metal quality and fast production times.

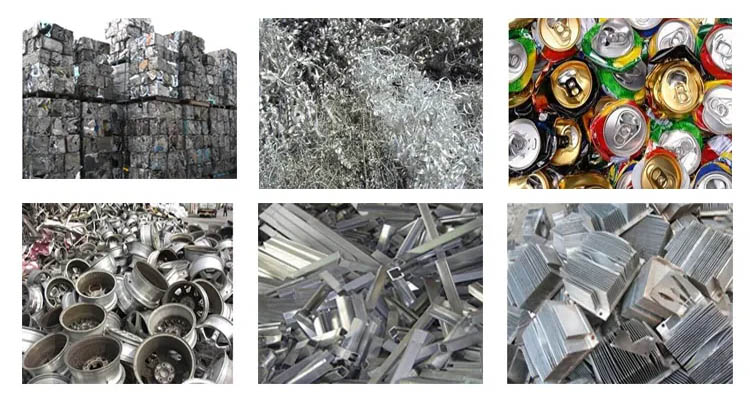

- Scrap Metal Recycling: Perfect for melting aluminum scrap, which can then be processed into ingots for reuse in other manufacturing processes.

Metal Alloy Production: Suitable for producing metal alloys, the furnace can melt aluminum and other non-ferrous metals like copper and zinc, making it highly versatile.

Why Oil Fired Furnaces Over Electric Models?

While electric aluminium furnaces offer some advantages, oil-fired furnaces provide several key benefits that make them a better choice for many factories:

- Lower Operational Costs: Oil is often cheaper than electricity, leading to significant savings in the long run.

- Faster Melting Times: Oil-fired furnaces generally achieve higher temperatures more quickly than electric furnaces, reducing the melting time and improving production efficiency.

- Greater Flexibility: The ability to use different fuel sources—such as light diesel or natural gas—gives you more control over your energy costs and sourcing.

Frequently Asked Questions (FAQ)

Q1: What is the average melting time for aluminum?

A: Melting time typically ranges from 1.5 to 2 hours, depending on the furnace capacity and initial temperature.

Q2: How much oil does the furnace consume per hour?

A: Fuel consumption varies depending on the model. For example, the JY-350 consumes around 20 x 10⁴ Kcal/h, while larger models like the JY-1000 use 40 x 10⁴ Kcal/h.

Q3: Can I customize the furnace for my specific needs?

A: Absolutely! We offer full customization, including size, design, and functionality, to meet your factory’s unique requirements.

Q4: What is the warranty on the furnace?

A: All our furnaces come with a one-year warranty, covering any manufacturing defects or issues with parts.